Page 131 - The Mechatronics Handbook

P. 131

While it is convenient to use power and energy in formulating system models for mechanical systems,

a motional basis is critical for identifying interconnections and when formulating quantifiable mathe-

matical models. For many mechanical, translational, and rotational systems, it is sufficient to rely on

basic one-dimensional motion and relative motion concepts to identify the interrelation between many

types of practical components. Identifying network-like structure in these systems has been the basis for

building electrical analogies for some time. These methods, as well as signal-flow analysis techniques,

are not presented here but are the method of choice in some approaches to system dynamics [33]. Bond

graph models are presented, and it will be shown in later sections how these are consistent even with

more complex mechanical system formulations of three-dimensional dynamics as well as with the use

of Lagrangian models.

Need for Motional Basis

In modeling mechanical translational or rotational systems, it is important to identify how the configu-

ration changes, and a coordinate system should be defined and the effect of geometric changes identified.

It is assumed that the reader is familiar with these basic concepts [12]. Usually a reference configuration

is defined from which coordinates can be based. This is essential even for simple one-dimensional

translation or fixed-axis rotation. The minumum number of geometrically independent coordinates

required to describe the configuration of a system is traditionally defined as the degrees of freedom.

Constraints should be identified and can be used to choose the most convenient set of coordinates for

description of the system. We distinguish between degrees of freedom and the minimum number of

dynamic state variables that might be required to describe a system. These may be related, but they are

not necessarily the same variables or the same in number (e.g., a second-order system has two states but

is also referred to as a single degree of freedom system).

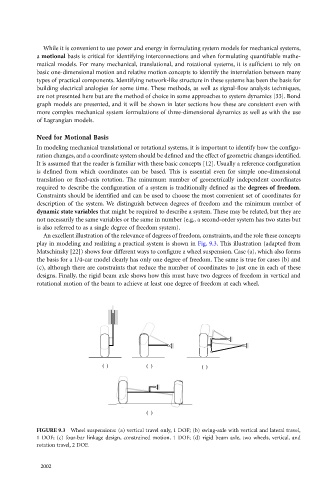

An excellent illustration of the relevance of degrees of freedom, constraints, and the role these concepts

play in modeling and realizing a practical system is shown in Fig. 9.3. This illustration (adapted from

Matschinsky [22]) shows four different ways to configure a wheel suspension. Case (a), which also forms

the basis for a 1/4-car model clearly has only one degree of freedom. The same is true for cases (b) and

(c), although there are constraints that reduce the number of coordinates to just one in each of these

designs. Finally, the rigid beam axle shows how this must have two degrees of freedom in vertical and

rotational motion of the beam to achieve at least one degree of freedom at each wheel.

(a) (b) (c)

(d)

FIGURE 9.3 Wheel suspensions: (a) vertical travel only, 1 DOF; (b) swing-axle with vertical and lateral travel,

1 DOF; (c) four-bar linkage design, constrained motion, 1 DOF; (d) rigid beam axle, two wheels, vertical, and

rotation travel, 2 DOF.

©2002 CRC Press LLC