Page 208 - Water Engineering Hydraulics, Distribution and Treatment

P. 208

186

Chapter 6

Water Distribution Systems: Components, Design, and Operation

root of the pressure. Minimum hydrant pressures of 50 psig

(347 kPa) cannot maintain standard fire streams after passing

through as little as 50 ft (15 m) of hose.

gauge

pitot

Motor pumpers commonly deliver up to 1,500 gpm

(5,677 L/min) at adequate pressures. Capacities of

20,000 gpm (75,700 L/min) are in sight, with single streams

discharging as much as 1,000 gpm (3,785 L/min) from 2 in.

(50 mm) nozzles. To furnish domestic and industrial draft and

keep pollution from entering water mains by seepage or fail-

ure under a vacuum, fire engines should not lower pressures

in the mains to less than 20 psig (140 kPa). For large hydrant

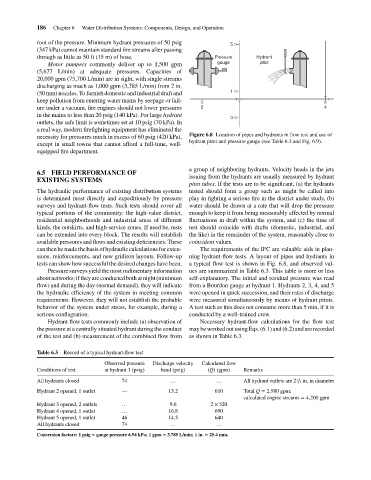

outlets, the safe limit is sometimes set at 10 psig (70 kPa). In 2 Pressure 5 1 3 Hydrant 4

a real way, modern firefighting equipment has eliminated the

necessity for pressures much in excess of 60 psig (420 kPa), Figure 6.8 Location of pipes and hydrants in flow test and use of

hydrant pitot and pressure gauge (see Table 6.3 and Fig. 6.9).

except in small towns that cannot afford a full-time, well-

equipped fire department.

a group of neighboring hydrants. Velocity heads in the jets

6.5 FIELD PERFORMANCE OF

issuing from the hydrants are usually measured by hydrant

EXISTING SYSTEMS

pitot tubes. If the tests are to be significant, (a) the hydrants

The hydraulic performance of existing distribution systems tested should form a group such as might be called into

is determined most directly and expeditiously by pressure play in fighting a serious fire in the district under study, (b)

surveys and hydrant-flow tests. Such tests should cover all water should be drawn at a rate that will drop the pressure

typical portions of the community: the high-value district, enough to keep it from being measurably affected by normal

residential neighborhoods and industrial areas of different fluctuations in draft within the system, and (c) the time of

kinds, the outskirts, and high-service zones. If need be, tests test should coincide with drafts (domestic, industrial, and

can be extended into every block. The results will establish the like) in the remainder of the system, reasonably close to

available pressures and flows and existing deficiencies. These coincident values.

can then be made the basis of hydraulic calculations for exten- The requirements of the IFC are valuable aids in plan-

sions, reinforcements, and new gridiron layouts. Follow-up ning hydrant-flow tests. A layout of pipes and hydrants in

tests can show how successful the desired changes have been. a typical flow test is shown in Fig. 6.8, and observed val-

Pressure surveys yield the most rudimentary information ues are summarized in Table 6.3. This table is more or less

about networks; if they are conducted both at night (minimum self-explanatory. The initial and residual pressure was read

flow) and during the day (normal demand), they will indicate from a Bourdon gauge at hydrant 1. Hydrants 2, 3, 4, and 5

the hydraulic efficiency of the system in meeting common were opened in quick succession, and their rates of discharge

requirements. However, they will not establish the probable were measured simultaneously by means of hydrant pitots.

behavior of the system under stress, for example, during a A test such as this does not consume more than 5 min, if it is

serious conflagration. conducted by a well-trained crew.

Hydrant-flow tests commonly include (a) observation of Necessary hydrant-flow calculations for the flow test

the pressure at a centrally situated hydrant during the conduct may be worked out using Eqs. (6.1) and (6.2) and are recorded

of the test and (b) measurement of the combined flow from as shown in Table 6.3.

Table 6.3 Record of a typical hydrant-flow test

Observed pressure Discharge velocity Calculated flow

Conditions of test at hydrant 1 (psig) head (psig) (Q) (gpm) Remarks

All hydrants closed 74 … … All hydrant outlets are 2 ∕ 2 in. in diameter

1

Hydrant 2 opened, 1 outlet — 13.2 610 Total Q = 2,980 gpm;

calculated engine streams = 4,200 gpm

Hydrant 3 opened, 2 outlets … 9.6 2 × 520

Hydrant 4 opened, 1 outlet … 16.8 690

Hydrant 5 opened, 1 outlet 46 14.5 640

All hydrants closed 74 … …

Conversion factors: 1 psig = gauge pressure 6.94 kPa; 1 gpm = 3.785 L/min; 1 in. = 25.4 mm.