Page 160 - Wire Bonding in Microelectronics

P. 160

Gold-Aluminum Intermetallic Compounds 137

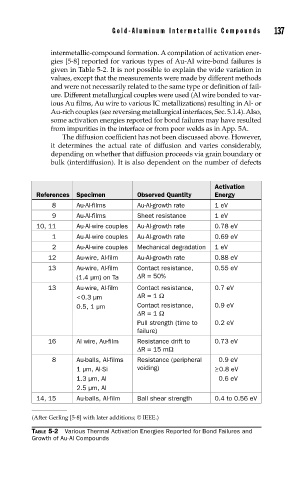

intermetallic-compound formation. A compilation of activation ener-

gies [5-8] reported for various types of Au-Al wire-bond failures is

given in Table 5-2. It is not possible to explain the wide variation in

values, except that the measurements were made by different methods

and were not necessarily related to the same type or definition of fail-

ure. Different metallurgical couples were used (Al wire bonded to var-

ious Au films, Au wire to various IC metallizations) resulting in Al- or

Au-rich couples (see reversing metallurgical interfaces, Sec. 5.1.4). Also,

some activation energies reported for bond failures may have resulted

from impurities in the interface or from poor welds as in App. 5A.

The diffusion coefficient has not been discussed above. However,

it determines the actual rate of diffusion and varies considerably,

depending on whether that diffusion proceeds via grain boundary or

bulk (interdiffusion). It is also dependent on the number of defects

Activation

References Specimen Observed Quantity Energy

8 Au-Al-films Au-Al-growth rate 1 eV

9 Au-Al-films Sheet resistance 1 eV

10, 11 Au-Al-wire couples Au-Al-growth rate 0.78 eV

1 Au-Al-wire couples Au-Al-growth rate 0.69 eV

2 Au-Al-wire couples Mechanical degradation 1 eV

12 Au-wire, Al-film Au-Al-growth rate 0.88 eV

13 Au-wire, Al-film Contact resistance, 0.55 eV

(1.4 µm) on Ta ∆R = 50%

13 Au-wire, Al-film Contact resistance, 0.7 eV

< 0.3 µm ∆R = 1 Ω

0.5, 1 µm Contact resistance, 0.9 eV

∆R = 1 Ω

Pull strength (time to 0.2 eV

failure)

16 Al wire, Au-film Resistance drift to 0.73 eV

∆R = 15 mΩ

8 Au-balls, Al-films Resistance (peripheral 0.9 eV

1 µm, Al-Si voiding) ≥ 0.8 eV

1.3 µm, Al 0.6 eV

2.5 µm, Al

14, 15 Au-balls, Al-film Ball shear strength 0.4 to 0.56 eV

(After Gerling [5-8] with later additions; © IEEE.)

TABLE 5-2 Various Thermal Activation Energies Reported for Bond Failures and

Growth of Au-Al Compounds