Page 161 - Wire Bonding in Microelectronics

P. 161

138 Cha pte r F i v e

available (the more defects, the faster diffusion proceeds). Aluminum

and other metals diffuse very rapidly into Au by grain-boundary dif-

fusion. A discussion of this is given in Sec. 6A.4. It should be noted that

the specific intermetallic compounds in a bond-interface area are

related to the relative amounts of Au and Al present and can be differ-

ent if Al metallization contains Cu or Si in the 1 to 2% level. In addition,

some compounds may be absent because of a low nucleation probabil-

ity (they do not get started) or they may grow very slowly and are not

observed.

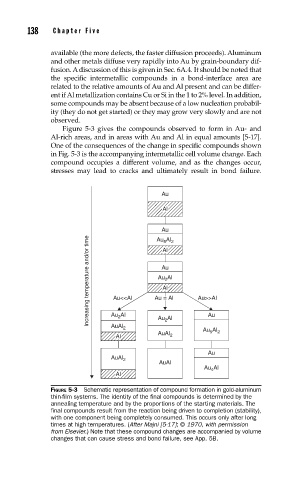

Figure 5-3 gives the compounds observed to form in Au- and

Al-rich areas, and in areas with Au and Al in equal amounts [5-17].

One of the consequences of the change in specific compounds shown

in Fig. 5-3 is the accompanying intermetallic cell volume change. Each

compound occupies a different volume, and as the changes occur,

stresses may lead to cracks and ultimately result in bond failure.

Au

Al

Au 2

Increasing temperature and/or time Au<<Al Au = Al Au>>Al

Au Al

5

Al

Au

Au Al

2

Al

Au Al

Au

2

Au Al

2

AuAl

2

Au Al 2

5

Al AuAl 2

Au

AuAl 2

AuAl

Al

Au 4

Al

FIGURE 5-3 Schematic representation of compound formation in gold-aluminum

thin-fi lm systems. The identity of the fi nal compounds is determined by the

annealing temperature and by the proportions of the starting materials. The

fi nal compounds result from the reaction being driven to completion (stability),

with one component being completely consumed. This occurs only after long

times at high temperatures. (After Majni [5-17]; © 1970, with permission

from Elsevier.) Note that these compound changes are accompanied by volume

changes that can cause stress and bond failure, see App. 5B.