Page 476 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 476

CHAP TER 1 5. 1 Modelling and assembly of the full vehicle

Δv

Z

Δγ

X

Y

Δz

Δx Δδ

Fxt

Fxb

Fy

Mz

Wheel

trajectory

Δy

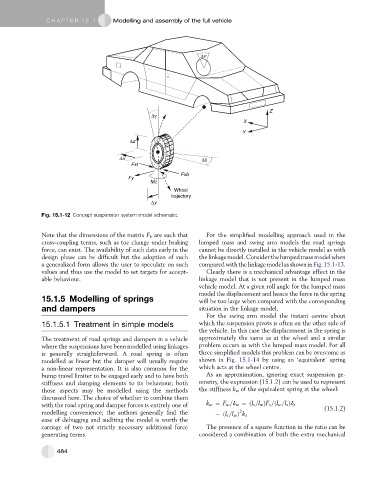

Fig. 15.1-12 Concept suspension system model schematic.

Note that the dimensions of the matrix F E are such that For the simplified modelling approach used in the

cross-coupling terms, such as toe change under braking lumped mass and swing arm models the road springs

force, can exist. The availability of such data early in the cannot be directly installed in the vehicle model as with

design phase can be difficult but the adoption of such thelinkagemodel.Considerthelumpedmassmodelwhen

a generalized form allows the user to speculate on such compared with thelinkage modelas shownin Fig. 15.1-13.

values and thus use the model to set targets for accept- Clearly there is a mechanical advantage effect in the

able behaviour. linkage model that is not present in the lumped mass

vehicle model. At a given roll angle for the lumped mass

model the displacement and hence the force in the spring

15.1.5 Modelling of springs will be too large when compared with the corresponding

and dampers situation in the linkage model.

For the swing arm model the instant centre about

15.1.5.1 Treatment in simple models which the suspension pivots is often on the other side of

the vehicle. In this case the displacement in the spring is

The treatment of road springs and dampers in a vehicle approximately the same as at the wheel and a similar

where the suspensions have been modelled using linkages problem occurs as with the lumped mass model. For all

is generally straightforward. A road spring is often three simplified models this problem can be overcome as

modelled as linear but the damper will usually require shown in Fig. 15.1-14 by using an ‘equivalent’ spring

a non-linear representation. It is also common for the which acts at the wheel centre.

bump travel limiter to be engaged early and to have both As an approximation, ignoring exact suspension ge-

stiffness and damping elements to its behaviour; both ometry, the expression (15.1.2) can be used to represent

those aspects may be modelled using the methods the stiffness k w of the equivalent spring at the wheel:

discussed here. The choice of whether to combine them

with the road spring and damper forces is entirely one of k w ¼ F w =d w ¼ðl s =l w ÞF s =ðl w =l s Þd s (15.1.2)

modelling convenience; the authors generally find the ¼ðl s =l w Þ k s

2

ease of debugging and auditing the model is worth the

carriage of two not strictly necessary additional force The presence of a square function in the ratio can be

generating terms. considered a combination of both the extra mechanical

484