Page 481 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 481

Modelling and assembly of the full vehicle C HAPTER 15.1

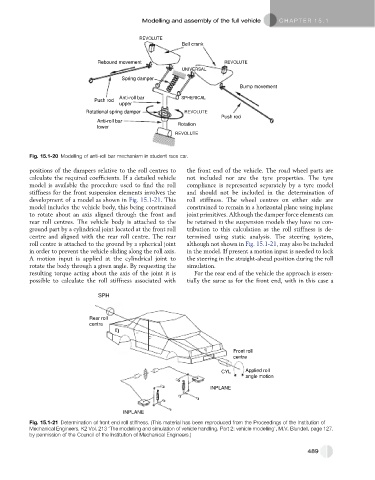

REVOLUTE

Bell crank

Rebound movement REVOLUTE

UNIVERSAL

Spring damper

Bump movement

Anti-roll bar SPHERICAL

Push rod

upper

Rotational spring damper REVOLUTE

Push rod

Anti-roll bar

lower Rotation

REVOLUTE

Fig. 15.1-20 Modelling of anti-roll bar mechanism in student race car.

positions of the dampers relative to the roll centres to the front end of the vehicle. The road wheel parts are

calculate the required coefficients. If a detailed vehicle not included nor are the tyre properties. The tyre

model is available the procedure used to find the roll compliance is represented separately by a tyre model

stiffness for the front suspension elements involves the and should not be included in the determination of

development of a model as shown in Fig. 15.1-21. This roll stiffness. The wheel centres on either side are

model includes the vehicle body, this being constrained constrained to remain in a horizontal plane using inplane

to rotate about an axis aligned through the front and joint primitives. Although the damper force elements can

rear roll centres. The vehicle body is attached to the be retained in the suspension models they have no con-

ground part by a cylindrical joint located at the front roll tribution to this calculation as the roll stiffness is de-

centre and aligned with the rear roll centre. The rear termined using static analysis. The steering system,

roll centre is attached to the ground by a spherical joint although not shown in Fig. 15.1-21, may also be included

in order to prevent the vehicle sliding along the roll axis. in the model. If present a motion input is needed to lock

A motion input is applied at the cylindrical joint to the steering in the straight-ahead position during the roll

rotate the body through a given angle. By requesting the simulation.

resulting torque acting about the axis of the joint it is For the rear end of the vehicle the approach is essen-

possible to calculate the roll stiffness associated with tially the same as for the front end, with in this case a

SPH

Rear roll

centre

Front roll

centre

CYL Applied roll

angle motion

INPLANE

INPLANE

Fig. 15.1-21 Determination of front end roll stiffness. (This material has been reproduced from the Proceedings of the Institution of

Mechanical Engineers, K2 Vol. 213 ‘The modelling and simulation of vehicle handling. Part 2: vehicle modelling’, M.V. Blundell, page 127,

by permission of the Council of the Institution of Mechanical Engineers.)

489