Page 480 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 480

CHAP TER 1 5. 1 Modelling and assembly of the full vehicle

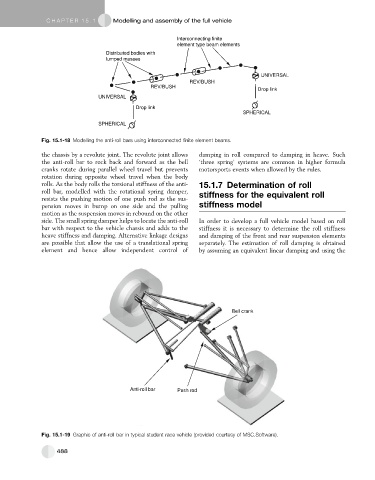

Interconnecting finite

element type beam elements

Distributed bodies with

lumped masses

UNIVERSAL

REV/BUSH

REV/BUSH

Drop link

UNIVERSAL

Drop link

SPHERICAL

SPHERICAL

Fig. 15.1-18 Modelling the anti-roll bars using interconnected finite element beams.

the chassis by a revolute joint. The revolute joint allows damping in roll compared to damping in heave. Such

the anti-roll bar to rock back and forward as the bell ‘three spring’ systems are common in higher formula

cranks rotate during parallel wheel travel but prevents motorsports events when allowed by the rules.

rotation during opposite wheel travel when the body

rolls. As the body rolls the torsional stiffness of the anti- 15.1.7 Determination of roll

roll bar, modelled with the rotational spring damper, stiffness for the equivalent roll

resists the pushing motion of one push rod as the sus-

pension moves in bump on one side and the pulling stiffness model

motion as the suspension moves in rebound on the other

side. The small spring damper helps to locate the anti-roll In order to develop a full vehicle model based on roll

bar with respect to the vehicle chassis and adds to the stiffness it is necessary to determine the roll stiffness

heave stiffness and damping. Alternative linkage designs and damping of the front and rear suspension elements

are possible that allow the use of a translational spring separately. The estimation of roll damping is obtained

element and hence allow independent control of by assuming an equivalent linear damping and using the

Bell crank

Anti-roll bar Push rod

Fig. 15.1-19 Graphic of anti-roll bar in typical student race vehicle (provided courtesy of MSC.Software).

488