Page 493 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 493

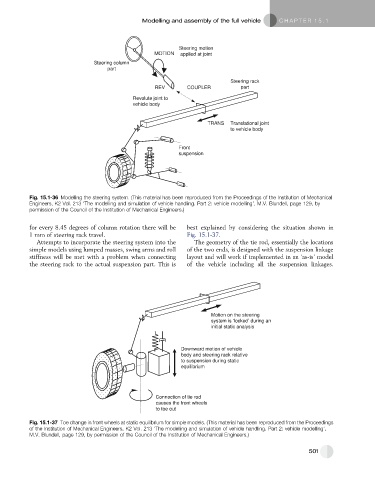

Modelling and assembly of the full vehicle C HAPTER 15.1

Steering motion

MOTION applied at joint

Steering column

part

Steering rack

REV COUPLER part

Revolute joint to

vehicle body

TRANS Translational joint

to vehicle body

Front

suspension

Fig. 15.1-36 Modelling the steering system. (This material has been reproduced from the Proceedings of the Institution of Mechanical

Engineers, K2 Vol. 213 ‘The modelling and simulation of vehicle handling. Part 2: vehicle modelling’, M.V. Blundell, page 129, by

permission of the Council of the Institution of Mechanical Engineers.)

for every 8.45 degrees of column rotation there will be best explained by considering the situation shown in

1 mm of steering rack travel. Fig. 15.1-37.

Attempts to incorporate the steering system into the The geometry of the tie rod, essentially the locations

simple models using lumped masses, swing arms and roll of the two ends, is designed with the suspension linkage

stiffness will be met with a problem when connecting layout and will work if implemented in an ‘as-is’ model

the steering rack to the actual suspension part. This is of the vehicle including all the suspension linkages.

Motion on the steering

system is ‘locked’ during an

initial static analysis

Downward motion of vehicle

body and steering rack relative

to suspension during static

equilibrium

Connection of tie rod

causes the front wheels

to toe out

Fig. 15.1-37 Toe change in front wheels at static equilibrium for simple models. (This material has been reproduced from the Proceedings

of the Institution of Mechanical Engineers, K2 Vol. 213 ‘The modelling and simulation of vehicle handling. Part 2: vehicle modelling’,

M.V. Blundell, page 129, by permission of the Council of the Institution of Mechanical Engineers.)

501