Page 509 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 509

Modelling and assembly of the full vehicle C HAPTER 15.1

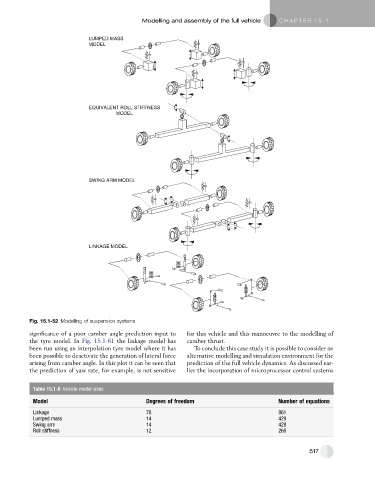

LUMPED MASS

MODEL

EQUIVALENT ROLL STIFFNESS

MODEL

SWING ARM MODEL

LINKAGE MODEL

Fig. 15.1-52 Modelling of suspension systems

significance of a poor camber angle prediction input to for this vehicle and this manoeuvre to the modelling of

the tyre model. In Fig. 15.1-61 the linkage model has camber thrust.

been run using an interpolation tyre model where it has To conclude this case study it is possible to consider an

been possible to deactivate the generation of lateral force alternative modelling and simulation environment for the

arising from camber angle. In this plot it can be seen that prediction of the full vehicle dynamics. As discussed ear-

the prediction of yaw rate, for example, is not sensitive lier the incorporation of microprocessor control systems

Table 15.1-6 Vehicle model sizes

Model Degrees of freedom Number of equations

Linkage 78 961

Lumped mass 14 429

Swing arm 14 429

Roll stiffness 12 265

517