Page 45 - Biaxial Multiaxial Fatigue and Fracture

P. 45

30 G. SAVAIDIS ETAL.

\

\ critical plane approach

- \ applying the shear

a,

> stress (mode II + Ill) criterion

a, -

1,20 0 \

- \

0

\

\

critical plane approach \

applying the normal \

oo stress (mode I) criterion 0 \

0:98

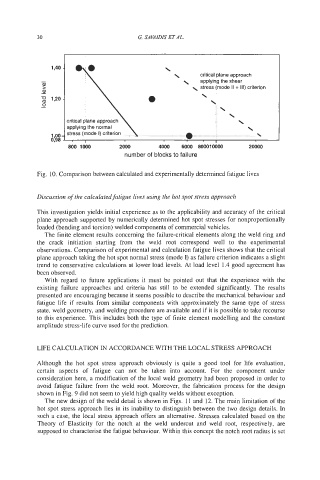

Fig. IO. Comparison between calculated and experimentally determined fatigue lives

Discussion of the calculated fatigue lives using the hot spot stress approach

This investigation yields initial experience as to the applicability and accuracy of the critical

plane approach supported by numerically determined hot spot stresses for nonproportionally

loaded (bending and torsion) welded components of commercial vehicles.

The finite element results concerning the failure-critical elements along the weld ring and

the crack initiation starting from the weld root correspond well to the experimental

observations. Comparison of experimental and calculation fatigue lives shows that the critical

plane approach taking the hot spot normal stress (mode I) as failure criterion indicates a slight

trend to conservative calculations at lower load levels. At load level 1.4 good agreement has

been observed.

With regard to future applications it must be pointed out that the experience with the

existing failure approaches and criteria has still to be extended significantly. The results

presented are encouraging because it seems possible to describe the mechanical behaviour and

fatigue life if results from similar components with approximately the same type of stress

state, weld geometry, and welding procedure are available and if it is possible to take recourse

to this experience. This includes both the type of finite element modelling and the constant

amplitude stress-life curve used for the prediction.

LIFE CALCULATION IN ACCORDANCE WITH THE LOCAL STRESS APPROACH

Although the hot spot stress approach obviously is quite a good tool for life evaluation,

certain aspects of fatigue can not be taken into account. For the component under

consideration here, a modification of the local weld geometry had been proposed in order to

avoid fatigue failure from the weld root. Moreover, the fabrication process for the design

shown in Fig. 9 did not seem to yield high quality welds without exception.

The new design of the weld detail is shown in Figs. 11 and 12. The main limitation of the

hot spot stress approach lies in its inability to distinguish between the two design details. In

such a case, the local stress approach offers an alternative. Stresses calculated based on the

Theory of Elasticity for the notch at the weld undercut and weld root, respectively, are

supposed to characterise the fatigue behaviour. Within this concept the notch root radius is set