Page 146 - Defrosting for Air Source Heat Pump

P. 146

Investigation of effect on uneven defrosting performance 139

2.0

1.9

1.8

1.7

1.6 The average value during a heat (froting) operation

V air (m s –1 ) 1.5

1.4

1.3

1.2

–1

1.1 1.3 m s

1.0

0 400 800 1200 16002000 240028003200 3600

Time (s)

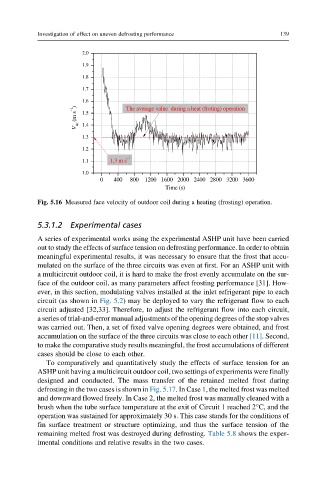

Fig. 5.16 Measured face velocity of outdoor coil during a heating (frosting) operation.

5.3.1.2 Experimental cases

A series of experimental works using the experimental ASHP unit have been carried

out to study the effects of surface tension on defrosting performance. In order to obtain

meaningful experimental results, it was necessary to ensure that the frost that accu-

mulated on the surface of the three circuits was even at first. For an ASHP unit with

a multicircuit outdoor coil, it is hard to make the frost evenly accumulate on the sur-

face of the outdoor coil, as many parameters affect frosting performance [31]. How-

ever, in this section, modulating valves installed at the inlet refrigerant pipe to each

circuit (as shown in Fig. 5.2) may be deployed to vary the refrigerant flow to each

circuit adjusted [32,33]. Therefore, to adjust the refrigerant flow into each circuit,

a series of trial-and-error manual adjustments of the opening degrees of the stop valves

was carried out. Then, a set of fixed valve opening degrees were obtained, and frost

accumulation on the surface of the three circuits was close to each other [11]. Second,

to make the comparative study results meaningful, the frost accumulations of different

cases should be close to each other.

To comparatively and quantitatively study the effects of surface tension for an

ASHP unit having a multicircuit outdoor coil, two settings of experiments were finally

designed and conducted. The mass transfer of the retained melted frost during

defrosting in the two cases is shown in Fig. 5.17. In Case 1, the melted frost was melted

and downward flowed freely. In Case 2, the melted frost was manually cleaned with a

brush when the tube surface temperature at the exit of Circuit 1 reached 2°C, and the

operation was sustained for approximately 30 s. This case stands for the conditions of

fin surface treatment or structure optimizing, and thus the surface tension of the

remaining melted frost was destroyed during defrosting. Table 5.8 shows the exper-

imental conditions and relative results in the two cases.