Page 299 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 299

P1: FYK/LPB P2: FPP Final

Encyclopedia of Physical Science and Technology EN006C-252 June 27, 2001 14:15

Fluid Mixing 99

done on the proper design and flaring of these tubes for

special applications. The main use of draft tube circula-

tors has been in precipitators and crystallizers. A further

requirement is that the liquid level be relatively uniform

in depth above the top of the draft tube, which means that

variable liquid levels are not practical with draft tube sys-

tems. In addition, slots are often provided at the bottom

of the draft tube, so that should a power failure occur and

solids settle at the bottom of the tank, flow can be passed

through these slots and scrub out particles at the bottom

of the tank for resuspension.

Sometimes it is desired to have a large working area in

a tank where, for example, a conveyor belt containing car

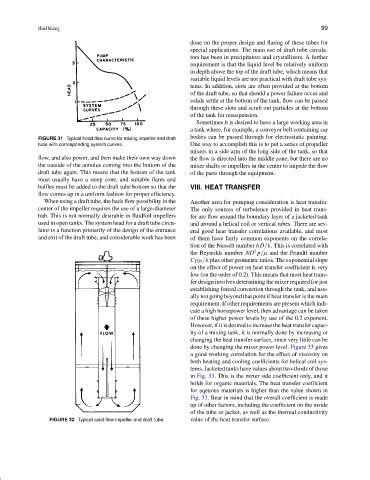

FIGURE 31 Typical head flow curve for mixing impeller and draft bodies can be passed through for electrostatic painting.

tube with corresponding system curves. One way to accomplish this is to put a series of propeller

mixers in a side arm of the long side of the tank, so that

flow, and also power, and then make their own way down the flow is directed into the middle zone, but there are no

the outside of the annulus coming into the bottom of the mixer shafts or impellers in the center to impede the flow

draft tube again. This means that the bottom of the tank of the parts through the equipment.

must usually have a steep cone, and suitable flares and

baffles must be added to the draft tube bottom so that the VIII. HEAT TRANSFER

flow comes up in a uniform fashion for proper efficiency.

When using a draft tube, the back flow possibility in the Another area for pumping consideration is heat transfer.

center of the impeller requires the use of a large-diameter The only sources of turbulence provided in heat trans-

hub. This is not normally desirable in fluidfoil impellers fer are flow around the boundary layer of a jacketed tank

used in open tanks. The system head for a draft tube circu- and around a helical coil or vertical tubes. There are sev-

lator is a function primarily of the design of the entrance eral good heat transfer correlations available, and most

and exit of the draft tube, and considerable work has been of them have fairly common exponents on the correla-

tion of the Nusselt number hD/k. This is correlated with

2

the Reynolds number ND p /µ and the Prandtl number

Cpµ/k plus other geometric ratios. The exponential slope

on the effect of power on heat transfer coefficient is very

low (on the order of 0.2). This means that most heat trans-

fer design involves determining the mixer required for just

establishing forced convection through the tank, and usu-

ally not going beyond that point if heat transfer is the main

requirement. If other requirements are present which indi-

cate a high horsepower level, then advantage can be taken

of these higher power levels by use of the 0.2 exponent.

However, if it is desired to increase the heat transfer capac-

ity of a mixing tank, it is normally done by increasing or

changing the heat transfer surface, since very little can be

done by changing the mixer power level. Figure 33 gives

a good working correlation for the effect of viscosity on

both heating and cooling coefficients for helical coil sys-

tems. Jacketed tanks have values about two-thirds of those

in Fig. 33. This is the mixer side coefficient only, and it

holds for organic materials, The heat transfer coefficient

for aqeuous materials is higher than the value shown in

Fig. 33. Bear in mind that the overall coefficient is made

up of other factors, including the coefficient on the inside

of the tube or jacket, as well as the thermal conductivity

FIGURE 32 Typical axial flow impeller and draft tube. value of the heat transfer surface.