Page 107 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 107

Engineering Design with SOLIDWORKS® 2018 Fundamentals of Part Modeling

PLATE Part- Extruded Cut Feature

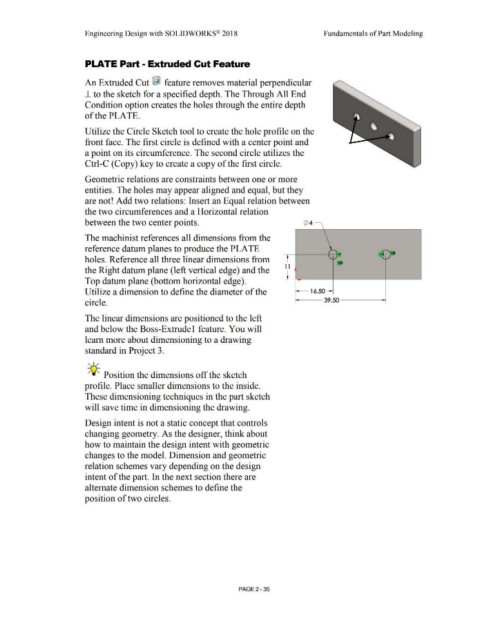

An Extruded Cut ~ feature removes material perpendicular

1- to the sketch for a specified depth. The Through All End

Condition option creates the holes through the entire depth

of the PLATE.

Utilize the Circle Sketch tool to create the hole profile on the

front face. The first circle is defined with a center point and

a point on its circumference. The second circle utilizes the

Ctrl-C (Copy) key to create a copy of the first circle.

Geometric relations are constraints between one or more

entities. The holes may appear aligned and equal, but they

are not! Add two relations: Insert an Equal relation between

the two circumferences and a Horizontal relation

between the two center points. <t>4

\

The machinist references all dimensions from the

reference datum planes to produce the PLATE L

' + .... 4 .~Qifl

¥

holes. Reference all three linear dimensions from • - ~

1 1

the Right datum plane (left vertical edge) and the I

Top datum plane (bottom horizontal edge). '

Utilize a dimension to define the diameter of the 16.50 --

circle. 39.50

The linear dimensions are positioned to the left

and below the Boss-Extrude 1 feature. You will

learn more about dimensioning to a drawing

standard in Project 3.

, 1 /

-;Q~ Position the dimensions off the sketch

profile. Place smaller dimensions to the inside.

These dimensioning techniques in the part sketch

will save time in dimensioning the drawing.

Design intent is not a static concept that controls

changing geometry. As the designer, think about

how to maintain the design intent with geometric

changes to the model. Dimension and geometric

relation schemes vary depending on the design

intent of the part. In the next section there are

alternate dimension schemes to define the

position of two circles.

PAGE2 -35