Page 254 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 254

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

51 O) Click OK from the Browse For Folder dialog box.

Save the model.

511) Click Save. The CUSTOMER assembly remains open.

Close all files.

512) Click Windows, Close All from the Menu bar.

513) Click Yes. View the saved assembly in the CopiedModels folder.

>

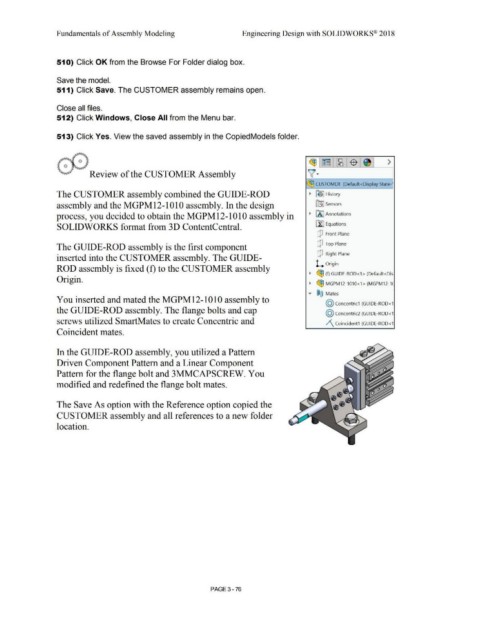

~ CUSTOMER (Default<Display State-

The CUSTOMER assembly combined the GUIDE-ROD • ~ -] History

assembly and the MGPM12-1010 assembly. In the design [0J Sensors

process, you decided to obtain the MGPM12-1010 assembly in • [A J Annotations

SOLIDWORKS format from 3D ContentCentral. [I] Equations

Q Front Plane

Q Top Plane

The GUIDE-ROD assembly is the first component

Q Right Plane

inserted into the CUSTOMER assembly. The GUIDE-

L. Origin

ROD assembly is fixed (f) to the CUSTOMER assembly

• ~ (f) GUIDE-ROD<1 > (Default<Dis

Origin.

• ~ MGPM12-1010<1 > (MGPM12-1C

.... ®@ Mates

You inserted and mated the MGPM12-1010 assembly to

@ concentric1 (GUIDE-ROD<1

the GUIDE-ROD assembly. The flange bolts and cap

@ concentric2 (GUIDE-ROD<1

screws utilized SmartMates to create Concentric and /\ Coincident1 (GUIDE-ROD<1

Coincident mates.

In the GUIDE-ROD assembly, you utilized a Pattern

Driven Component Pattern and a Linear Component

Pattern for the flange bolt and 3MMCAPSCREW. You

modified and redefined the flange bolt mates.

The Save As option with the Reference option copied the

CUSTOMER assembly and all references to a new folder

location.

PAGE 3-76