Page 576 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 576

Top-Down and Sheet Metal Parts Engineering Design with SOLIDWORKS® 2018

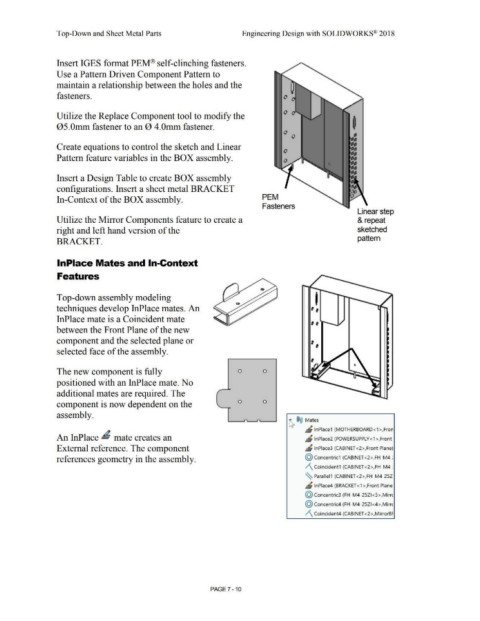

Insert IGES format PEM® self-clinching fasteners.

Use a Pattern Driven Component Pattern to

maintain a relationship between the holes and the

fasteners.

Utilize the Replace Component tool to modify the

05.0mm fastener to an 0 4.0mm fastener.

Create equations to control the sketch and Linear

Pattern feature variables in the BOX assembly.

Insert a Design Table to create BOX assembly

configurations. Insert a sheet metal BRACKET

In-Context of the BOX assembly. PEM

Fasteners

Linear step

Utilize the Mirror Components feature to create a & repeat

right and left hand version of the sketched

pattern

BRACKET.

lnPlace Mates and In-Context

Features

Top-down assembly modeling I

techniques develop InPlace mates. An ,,

InPlace mate is a Coincident mate ,,

between the Front Plane of the new

component and the selected plane or ,,

selected face of the assembly.

The new component is fully 0 0

positioned with an InPlace mate. No

,

additional mates are required. The

component is now dependent on the 0 0

assembly.

~ ®@ Mates

" lnPlace1 (MOTHERBOARD<1 >,Fron

An InPlace ~ mate creates an ~ lnPlace2 (POWERSUPPLY<1>,Front

External reference. The component ~ lnPlace3 (CABINET <2>,Front Plane)

references geometry in the assembly. @ concentric1 (CABINET <2>,FH-M4-:

/\ Coincident1 (CABINET <2>,FH-M4-:

~ Parallel1 (CABINET <2>,FH-M4-25Z

JS lnPlace4 (BRACKET <1 >,Front Plane:

@ concentric3 (FH-M4-25ZI <5>,Mirrc

@ concentric4 (FH-M4-25Z1 <4>,Mirrc

/\ Coincident4 (CABINET <2>,MirrorBF

PAGE 7 - 10