Page 602 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 602

Top-Down and Sheet Metal Parts Engineering Design with SOLIDWORKS® 2018

Example:

T is the Material thickness.

Create a 90° bend with an inside radius of R:

L = Yz nR + 8T

The ratio between 8 and Tis called the K-factor. Let K = 0.41 for Aluminum:

K=8/T

8=KT=0.41T

L = Yz nR + 0. 41 T

U.S. Sheet metal shops use their own numbers.

Example:

One shop may use K = 0.41 for Aluminum, versus another shop that uses K = 0.45.

Use tables, manufacturer's specifications or experience.

Save design time and manufacturing time. Work with your Sheet Type and Size

~ ~~

metal shop to know their K-factor. Material and their equipment

produce different values. Build these values into the initial -

~ 10.00 Open

design.

~ O.lOmm

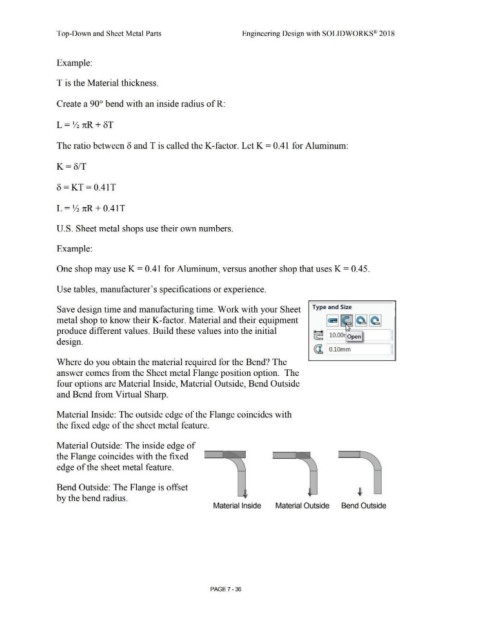

Where do you obtain the material required for the Bend? The

answer comes from the Sheet metal Flange position option. The

four options are Material Inside, Material Outside, Bend Outside

and Bend from Virtual Sharp.

Material Inside: The outside edge of the Flange coincides with

the fixed edge of the sheet metal feature.

Material Outside: The inside edge of

the Flange coincides with the fixed

edge of the sheet metal feature.

Bend Outside: The Flange is offset

by the bend radius.

Material Inside Material Outside Bend Outside

PAGE? - 36