Page 603 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 603

Engineering Design with SOLIDWORKS® 2018 Top-Down and Sheet Metal Parts

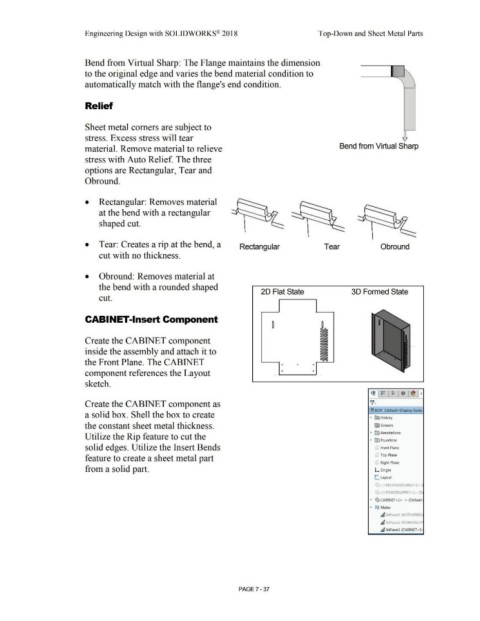

Bend from Virtual Sharp: The Flange maintains the dimension

to the original edge and varies the bend material condition to

automatically match with the flange's end condition.

Relief

Sheet metal comers are subject to

stress. Excess stress will tear i

material. Remove material to relieve Bend from Virtual Sharp

stress with Auto Relief. The three

options are Rectangular, Tear and

Obround.

• Rectangular: Removes material

at the bend with a rectangular

shaped cut.

• Tear: Creates a rip at the bend, a Rectangular Tear Obround

cut with no thickness.

• Obround: Removes material at

the bend with a rounded shaped

20 Flat State 30 Formed State

cut.

CABINET-Insert Component

~

a

D

D

Create the CABINET component D

a

D .

D •

inside the assembly and attach it to D

D

D

D

D

the Front Plane. The CABINET • • •

component references the Layout • •

sketch.

Create the CABINET component as

(!) BOX (Default< Display State·

a solid box. Shell the box to create • ~ History

the constant sheet metal thickness. l'srJ Sensors

• [A) Annotations

Utilize the Rip feature to cut the

• ll'.) Equations

solid edges. Utilize the Insert Bends (!) Front Plane

feature to create a sheet metal part CJ Top Plane

(;] Right Plane

from a solid part. L Origin

L. Layout

(1J {·) MOTHERBOARD<!> (I

('~ {·) POWERSUPPLY<l> (D1

• (S:, CABINET <l > ·> (Default•

• @@ Mates

~ InPlacel (MOTHERBO,

~ InPlace2 (POWERSUPP

~ lnPlace3 (CABINET <l )

PAGE? - 37