Page 620 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 620

Top-Down and Sheet Metal Parts Engineering Design with SOLIDWORKS® 2018

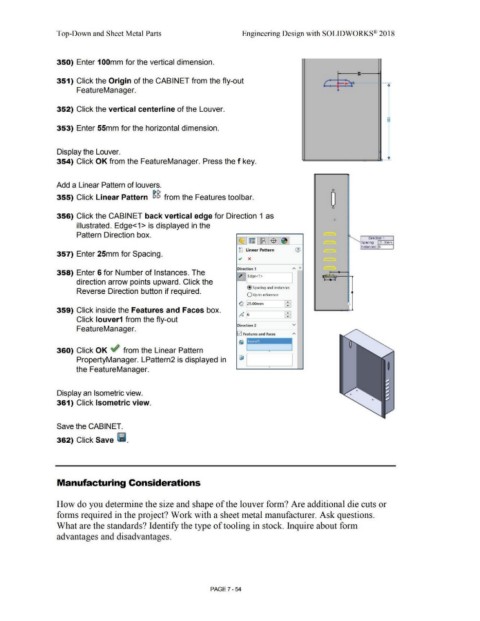

350) Enter 100mm for the vertical dimension.

8:

351) Click the Origin of the CABINET from the fly-out f , _ G-

FeatureManager. ~

352) Click the vertical centerline of the Louver.

-

8

353) Enter 55mm for the horizontal dimension.

Display the Louver.

354) Click OK from the FeatureManager. Press the f key.

Add a Linear Pattern of louvers.

[)C, 0

0

355) Click Linear Pattern eiei from the Features toolbar.

0

356) Click the CABINET back vertical edge for Direction 1 as

illustrated. Edge<1 > is displayed in the

Pattern Direction box.

Direction 1

,;;.--------1

Spacing: 25.00rnrn

Instances: 6

gg Linear Pattern

357) Enter 25mm for Spacing.

.; x

Direction 1 "" "

358) Enter 6 for Number of Instances. The

Z]~Edge<l>

direction arrow points upward. Click the

@ Spacing and instances

Reverse Direction button if required. •

O Up to reference

G 25.00mm

359) Click inside the Features and Faces box. 0

o"~ 6 - •

•

Click louver1 from the fly-out

Direction 2 v

FeatureManager.

!v'! Features and Faces

360) Click OK ~ from the Linear Pattern •

PropertyManager. LPattern2 is displayed in

the FeatureManager. I

Display an Isometric view.

361) Click Isometric view.

Save the CABINET.

362) Click Save Ii.

Manufacturing Considerations

How do you determine the size and shape of the louver form? Are additional die cuts or

forms required in the project? Work with a sheet metal manufacturer. Ask questions.

What are the standards? Identify the type of tooling in stock. Inquire about form

advantages and disadvantages.

PAGE? - 54