Page 209 - Finite Element Modeling and Simulations with ANSYS Workbench

P. 209

194 Finite Element Modeling and Simulation with ANSYS Workbench

p p

Internal forces:

p

p

Membrane stresses

dominate

FIGURE 6.9

Internal forces acting in a cylinder under internal pressure load.

6.3 Modeling of Plates and Shells

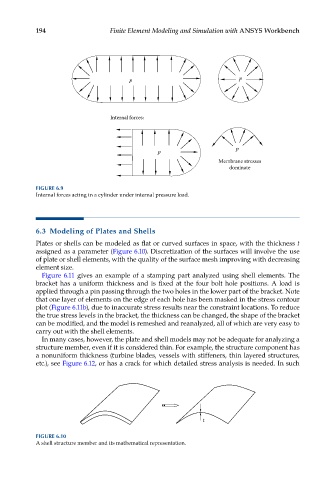

Plates or shells can be modeled as flat or curved surfaces in space, with the thickness t

assigned as a parameter (Figure 6.10). Discretization of the surfaces will involve the use

of plate or shell elements, with the quality of the surface mesh improving with decreasing

element size.

Figure 6.11 gives an example of a stamping part analyzed using shell elements. The

bracket has a uniform thickness and is fixed at the four bolt hole positions. A load is

applied through a pin passing through the two holes in the lower part of the bracket. Note

that one layer of elements on the edge of each hole has been masked in the stress contour

plot (Figure 6.11b), due to inaccurate stress results near the constraint locations. To reduce

the true stress levels in the bracket, the thickness can be changed, the shape of the bracket

can be modified, and the model is remeshed and reanalyzed, all of which are very easy to

carry out with the shell elements.

In many cases, however, the plate and shell models may not be adequate for analyzing a

structure member, even if it is considered thin. For example, the structure component has

a nonuniform thickness (turbine blades, vessels with stiffeners, thin layered structures,

etc.), see Figure 6.12, or has a crack for which detailed stress analysis is needed. In such

t

FIGURE 6.10

A shell structure member and its mathematical representation.