Page 404 - High Power Laser Handbook

P. 404

372 So l i d - S t at e La s e r s The National Ignition Facility Laser 373

200 20

180 Request 18

160 10 × Request 16

1st PQ

140 14

10 × 1st PQ 12

Power (mW) 100 2nd PQ 10 Power × 10 (mW)

120

10 × 2nd PQ

8

80

60 6

40 4

Power × 10

20 2

0 0

0 5 10 15 20 25

Time (ns)

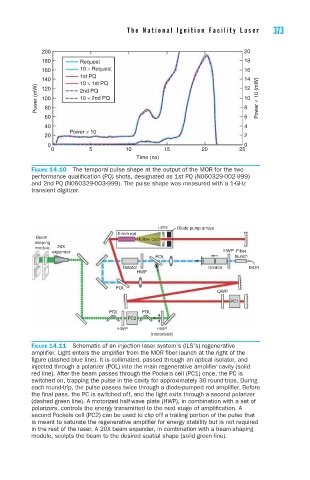

Figure 14.10 The temporal pulse shape at the output of the MOR for the two

performance qualification (PQ) shots, designated as 1st PQ (N060329-002-999)

and 2nd PQ (N060329-003-999). The pulse shape was measured with a 1-GHz

transient digitizer.

Lens Diode pump arrays

5-mm rod

Beam- Hollow duct

shaping

module 20X

expander HWP Fiber

POL launch

Rotator Isolator MOR

HWP

POL

QWP

PC1

POL POL

PC2

HWP HWP

(motorized)

Figure 14.11 Schematic of an injection laser system’s (ILS’s) regenerative

amplifier. Light enters the amplifier from the MOR fiber launch at the right of the

figure (dashed blue line). It is collimated, passed through an optical isolator, and

injected through a polarizer (POL) into the main regenerative amplifier cavity (solid

red line). After the beam passes through the Pockels cell (PC1) once, the PC is

switched on, trapping the pulse in the cavity for approximately 30 round-trips. During

each round-trip, the pulse passes twice through a diode-pumped rod amplifier. Before

the final pass, the PC is switched off, and the light exits through a second polarizer

(dashed green line). A motorized half-wave plate (HWP), in combination with a set of

polarizers, controls the energy transmitted to the next stage of amplification. A

second Pockels cell (PC2) can be used to clip off a trailing portion of the pulse that

is meant to saturate the regenerative amplifier for energy stability but is not required

in the rest of the laser. A 20X beam expander, in combination with a beam-shaping

module, sculpts the beam to the desired spatial shape (solid green line).