Page 114 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 114

Electrolytes 91

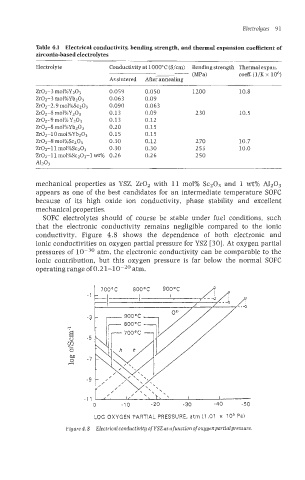

Table 4.1 Electrical conductivity, bending strength, and thermal expansion coefficient of

zirconia-based electrolytes

Electrolyte Conductivity at 1000°C (S/cm) Bending strength Thermal expan.

(MW coeff. (1/K x lo6)

As sintered After annealing

Zr02-3 mol%Y203 0.059 0.050 1200 10.8

Zr02-3 mol%Ybz03 0.063 0.09

Zr02-2.9 mo1%Sc2O3 0.090 0.063

Zr02-8 mol%Y203 0.13 0.09 230 10.5

Zr02-9 mol% YzO3 0.13 0.12

Zr02-8 mol%YbZO3 0.20 0.15

Zr02-10 mol%Yb203 0.15 0.15

Zr02-8 mol%Sc203 0.30 0.12 2 70 10.7

Zr02-ll mo1%Sc203 0.30 0.30 255 10.0

Zr02-11 mol%SczO3-l wt% 0.26 0.26 250

A1203

mechanical properties as YSZ. ZrOz with 11 mol% Sc203 and 1 wt% AI2O3

appears as one of the best candidates for an intermediate temperature SOFC

because of its high oxide ion conductivity, phase stability and exceIlent

mechanical properties.

SOFC electrolytes should of course be stable under fuel conditions, such

that the electronic conductivity remains negIigible compared to the ionic

conductivity. Figure 4.8 shows the dependence of both electronic and

ionic conductivities on oxygen partial pressure for YSZ [30]. At oxygen partial

pressures of atm, the electronic conductivity can be comparable to the

ionic contribution, but this oxygen pressure is far below the normal SOFC

operating range of 0.2 1-10-20 atm.

M

0

4

0 -10 -20 -30 -40 .50

LOG OXYGEN PARTIAL PRESSURE, atrn (1,Ol x 10’ Pa)

Figure 4.8 Electrical conductivity of YSZas a function of oxygenpartialpressure.