Page 118 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 118

Electrolytes 95

parabolic rate law as in the Wagner oxidation process. Thus, the film thickness,

L, is related to the deposition time, t, by the following equation:

L2 = 2$t (9)

where kp is the parabolic constant. At the deposition temperatures of

1000-1200°C, the parabolic rate constant for the deposition of YSZ ranges

from 1.1 x to 3.8 x cm2/s. The thickness of the YSZ film in a typical

tubular SOFC is about 40 pm and it takes about 40 minutes to make this film at

1000°C [41]. The EVD process has been successfully used by Westinghouse for

the production of thousands of tubular cells for several multikilowatt power

generation systems.

More conventional slurry dipping/sintering techniques have also been used to

prepare electrolyte films for tubular SOFCs, starting with a porous support which

can be of either anode, cathode or an inert material. Toto Ltd in Japan prepared

YSZ films on large size porous (La,Sr)Mn03 tubes, 22 mm in diameter and

900 mm in length E421 by a slurry dipping/sintering method. Thickness and gas

tightness of the YSZ layer depended on the speed of tube withdrawal from the

slurry, the number of dippings, and the viscosity of the slurry. Song e6 al. reported

that a dense YSZ film was obtained on a porous Ni-YSZ tube of effective area

20 cm2 at a withdrawal speed of 22 mm/s. A YSZ film of approximately 20 pm in

thickness was obtained from two slurry coats [43].

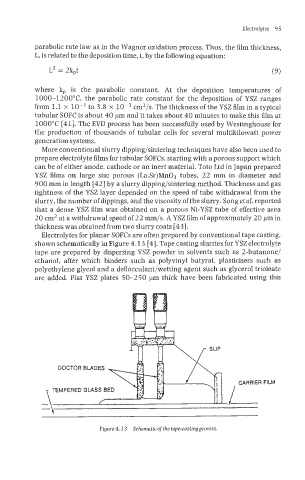

Electrolytes for planar SOFCs are often prepared by conventional tape casting,

shown schematically in Figure 4.13 [4]. Tape casting slurries for YSZ electrolyte

tape are prepared by dispersing YSZ powder in solvents such as 2-butanone/

ethanol, after which binders such as polyvinyl butyral, plasticisers such as

polyethylene glycol and a deflocculant/wetting agent such as glycerol trioleate

are added. Flat YSZ plates 50-250 pm thick have been fabricated using this

DOCTOR BLADES

MPERED QLASS

Figure 4.13 Schematic of the tape-castingprocess.