Page 119 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 119

96 High Temperature Solid Oxide Fuel Cells: Fundamentals, Design and Applications

method. Recently. electrode-supported cell designs have been extensively

studied because the electrolyte thickness can be much lower in these designs,

typically 5-20 ym, giving a much lower ohmic resistance than that of an

electrolyte supported cell. Thus, the electrode-supported cell design, in principle,

is better suited for operation at lower temperatures [44]. Anode-supported cells

are being developed using -10 pm thick tape cast YSZ electrolyte laminated onto

-600 pm thick tape cast Ni/YSZ anode and co-sintered at about 1350°C for 1 h.

Conventional screen printing techniques have also been used to prepare thin

electrolyte films in electrode-supported designs [45]. Cells with electrolyte

thicknesses between 3 and 30 ym have been fabricated. The total cell resistance

with a 4 pm thick electrolyte was 0.105 S2 cm2 at 700°C which corresponds to a

S/cm conductivity value of YSZ at 700°C. In Table 4.3, the preparation

methods for SOFC electrolytes used by several organisations are summarised.

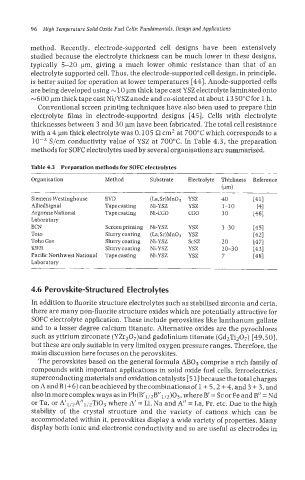

Table 4.3 Preparation methods for SOFC electrolytes

Organisation Method Substrate Electrolyte Thickness Reference

(r.tm)

Siemens Westinghouse EVD (La,Sr)Mn03 YSZ 40 r411

AlliedSignal Tape casting Nl-YSZ YSZ 1-10 [41

Argonne National Tape casting Ni-CGO CGO 30 ~461

Laboratory

ECN Screen printing Ni-YSZ YSZ 3-30 1451

Toto Slurry coating (La,Sr)MnOs YSZ ~421

Toho Gas Slurry coating Nl-YSZ scsz 20 [471

KIER Slurry coating Ni-YSZ YSZ 20-30 [43]

Pacific Northwest National Tape casting Ni-YSZ YSZ 7 1481

Laboratory

4.6 Perovskitestructured Electrolytes

In addition to fluorite structure electrolytes such as stabilised zirconia and ceria,

there are many non-fluorite structure oxides which are potentially attractive for

SOFC electrolyte application. These include perovskites like lanthanum gallate

and to a lesser degree calcium titanate. Alternative oxides are the pyrochlores

such as yttrium zirconate (YZr207)and gadolinium titanate (Gd2Ti207) [49,50],

but these are only suitable in very limited oxygen pressure ranges. Therefore, the

main discussion here focuses on the perovskites.

The perovskites based on the general formula ABO3 comprise a rich family of

compounds with important applications in solid oxide fuel ceIls, ferroeIectrics,

superconducting materials and oxidation catalysts [ 5 11 because the total charges

onAandB(+6)canbeachievedbythecombinationsofl+ 5,2 +4,and3 + 3,and

also in more complex ways as in Pb(B’1/2B’’1/2)03, where B’ = Sc or Fe and B” = Nd

or Ta, or A’1/2A”1/2Ti03 where A’ = Li, Na and A” = La, Pr, etc. Due to the high

stability of the crystal structure and the variety of cations which can be

accommodated within it, perovslcites display a wide variety of properties. Many

display both ionic and electronic conductivity and so are useful as electrodes in