Page 145 - Industrial Power Engineering and Applications Handbook

P. 145

Static controls and braking of motors 61125

Pulse widths

AC output

voltage pulses

AC input

instantaneous

voltage

waveform

C D ztl+fP+t3+t4+t5ft6

~

r

and V,,, = V,iC I

D F

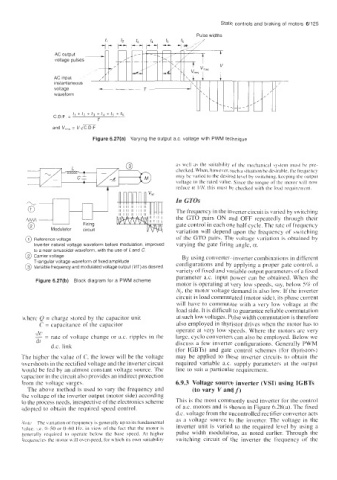

Figure 6.27(a) Varying the output a c voltage with PWM technique

ai wcll as the suitability of the mechanical sy\tein must he pre-

checked. When. however, such a situation be desirable. the frequency

may be varied to the desired lebel by twitching. kccping the output

voltage to the rated value. Since the torque of the motor will now

f reduce a IIN, this must be checked with the load requirement.

In GTOs

* The frequency in the inverter circuit is varied by switching

the GTO pairs ON and OFF repeatedly through their

I

Firing

Modulator circuit gate control in each one half cycle. The rate of frequency

variation will depend upon the frequency of switching

@) Reference voltage of the GTO pairs. The voltage variation is obtained by

Inverter natural voltage waveform before modulation improved varying the gate firing angle, a.

to a near sinusoidal waveform, with the use of Land C

@ Carrier voltage By using converter-inverter combinations in different

Triangular voltage waveform of fixed amplitude

@ Variable frequency and modulated voltage output (Vif ) as desired configurations and by applying a proper gate control. a

variety of fixed and variable output parameters of a fixed

parameter a.c. input power can be obtained. When the

Figure 6.27(b) Block diagram for a PWM scheme

motor is operating at very low speeds, say, below 5% of

N,, the motor voltage demand is also low. If the inverter

circuit is load commutated (motor side), its phase current

will have to commutate with a very low voltage at the

load side. It is difficult to guarantee reliable commutation

where Q = charge stored by the capacitor unit at such low voltages. Pulse width commutation is therefore

C = capacitance of the capacitor also employed in thyristor drives when the motor has to

du operate at very low speeds. Where the motors are very

- rate of voltage change or a.c. ripples in the large, cyclo converters can also be employed. Below we

=

dt discuss a few inverter configurations. Generally PWM

d.c. link

(for IGBTs) and gate control schemes (for thyristors)

The higher the value of C, the lower will be the voltage may be applied to these inverter circuits to obtain the

overshoots in the rectified voltage and the inverter circuit required variable a.c. supply parameters at the output

would be fed by an almost constant voltage source. The line to suit a particular requirement.

capacitor in the circuit also provides an indirect protection

from the voltage surges. 6.9.3 Voltage source inverter (VSI) using IGBTs

The above method is used to vary the frequency and (to vary V andf)

the voltage ot the inverter output (motor side) according

to the process needs, irrespective of the electronics scheme This is the most commonly used inverter for the control

adopted to obtain the required speed control. of a.c. motors and is shown in Figure 6.28(a). The fixed

d.c. voltage from the uncontrolled rectifier converter acts

as a voltage source to the inverter. The voltage in the

,Vrur The variation of frequency is generally up to its fundamental

value. ].e. 0-50 or 0-60 Hr. in vicw of the fact that the motor is inverter unit is varied to the required level by using a

generally required to operate below the base speed. At higher pulse width modulation, as noted earlier. Through the

frecpencie\ the motor \n ill overspeed. for v hich its own suitab~lity switching circuit of the inverter the frequency of the