Page 148 - Industrial Power Engineering and Applications Handbook

P. 148

6/128 Industrial Power Engineering and Applications Handbook

it is common practice to dissipate the heat of regeneration converter unit is capable of performing both the jobs,

in this way but in larger machines it can be a substantial converting the fixed a.c. supply to a fixed or variable d.c.

drain on the useful energy, particularly when the machine voltage to control an ax. machine and during a regenerative

is called upon to perform frequent variations of speed, mode, feeding the regenerative energy back to the source

reversals or brakings. It is, therefore, advisable to conserve of supply. A separate transformer will not be necessary

this energy by feeding it to the other drives or by now, as the same IGBT circuit will act as a regenerative

transferring it back to the source of supply, which can be inverter. The switching of an IGBT is now an easy feature.

done in the following ways. The harmonics are also too low, and the p.f. can be

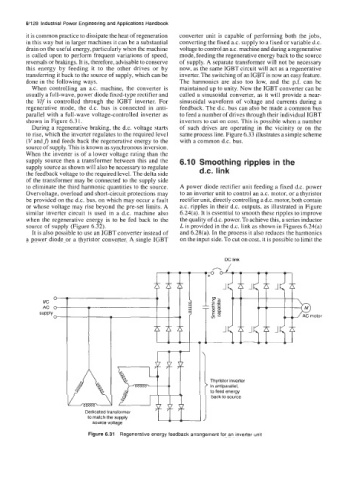

When controlling an ax. machine, the converter is maintained up to unity. Now the IGBT converter can be

usually a full-wave, power diode fixed-type rectifier and called a sinusoidal converter, as it will provide a near-

the Vlf is controlled through the IGBT inverter. For sinusoidal waveform of voltage and currents during a

regenerative mode, the d.c. bus is connected in anti- feedback. The d.c. bus can also be made a common bus

parallel with a full-wave voltage-controlled inverter as to feed a number of drives through their individual IGBT

shown in Figure 6.3 1. inverters to cut on cost. This is possible when a number

During a regenerative braking, the d.c. voltage starts of such drives are operating in the vicinity or on the

to rise, which the inverter regulates to the required level same process line. Figure 6.33 illustrates a simple scheme

(V andf) and feeds back the regenerative energy to the with a common d.c. bus.

source of supply. This is known as synchronous inversion.

When the inverter is of a lower voltage rating than the

supply source then a transformer between this and the 6.10 Smoothing ripples in the

supply source as shown will also be necessary to regulate

the feedback voltage to the required level. The delta side d.c. link

of the transformer may be connected to the supply side

to eliminate the third harmonic quantities to the source. A power diode rectifier unit feeding a fixed d.c. power

Overvoltage, overload and short-circuit protections may to an inverter unit to control an a.c. motor, or a thyristor

be provided on the d.c. bus, on which may occur a fault rectifier unit, directly controlling a d.c. motor, both contain

or whose voltage may rise beyond the pre-set limits. A ax. ripples in their d.c. outputs, as illustrated in Figure

similar inverter circuit is used in a d.c. machine also 6.24(a). It is essential to smooth these ripples to improve

when the regenerative energy is to be fed back to the the quality of d.c. power. To achieve this, a series inductor

source of supply (Figure 6.32). L is provided in the d.c. link as shown in Figures 6.24(a)

It is also possible to use an IGBT converter instead of and 6.28(a). In the process it also reduces the harmonics

a power diode or a thyristor converter. A single IGBT on the input side. To cut on cost, it is possible to limit the

DC link

I-... I , Thyristor inverter

-

to feed energy

back to source

Dedicated transformer > in antiparallel,

to match the supply

source voltage

Figure 6.31 Regenerative energy feedback arrangement for an inverter unit