Page 927 - Industrial Power Engineering and Applications Handbook

P. 927

Carrying power through metal-enclosed bus systems 28/877

of metal, particularly in larger sections. While larger

sections would be imperative for such large ratings, their

own rating would fall to a low of 14-1 8% of their normal

current capacity. (See Table 30.5 for larger sections,

providing current ratings up to six bars in parallel.) In

such cases it is advisable to arrange the bars in any other

convenient configuration than in parallel, as illustrated

in Figure 28.14 or to use round or channel sections to

achieve better results and a higher level of metal utilization. CL <q

28.7.2 Determining the skin effect

As a result of the electric field around the conductors the

frequency of the system has a very significant bearing

on the skin effect. The various curves as established

through experiments and, as reproduced in Figures 28.13 -___-

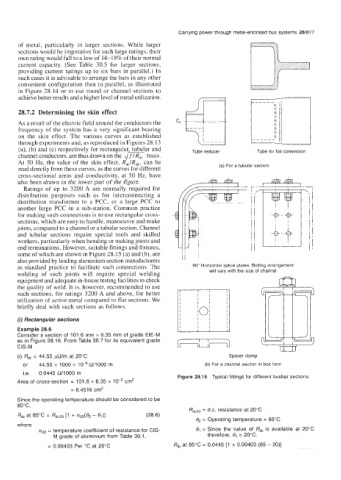

(a), (b) and (c) respectively for rectangular tubular and Tube reducer Tube for flat connection

channel conductors, are thus drawn on the ,/m basis.

At 50 Hz, the value of the skin effect, RaclRac, can be (a) For a tubular section

read directly from these curves, as the curves for different

cross-sectional areas and conductivity, at 50 Hz, have

also been drawn in the lower part of the figure.

Ratings of up to 3200 A are normally required for r;

distribution purposes such as for interconnecting a ii li

distribution transformer to a PCC, or a large PCC to 'i ii

another large PCC in a sub-station. Common practice

for making such connections is to use rectangular cross-

sections, which are easy to handle, manoeuvre and make i

joints, compared to a channel or a tubular section. Channel i

and tubular sections require special tools and skilled ii

workers, particularly when bending or making joints and

end terminations. However, suitable fittings and fixtures, ii

some of which are shown in Figure 28.15 (a) and (b), are ii 1

also provided by leading aluminium section manufacturers

as standard practice to facilitate such connections. The 90" Horizontal splice plates. Bolting arrangement

welding of such joints will require special welding will vary with the size of channel

equipment and adequate in-house testing facilities to check

the quality of weld. It is, however, recommended to use

such sections, for ratings 3200 A and above, for better

utilization of active metal compared to flat sections. We

briefly deal with such sections as follows. -

(i) Rectangular sections I I I I

Example 28.6 I I

Consider a section of 101.6 mm x 6.35 mm of grade EIE-M

as in Figure 28.16. From Table 30.7 for its equivalent grade

CIS-M

(i) Rdc = 44.55 mlm at 20°C Spacer clamp

or 44.55 x 1 000 x 1 O~ R/I 000 m (b) For a channel section in box form

Le. 0.0445 R/lOOO m

Figure 28.15 Typical fittings for different busbar sections

Area of cross-section = 101.6 x 6.35 x cm2

= 6.4516 cm2

Since the operating temperature should be considered to be

85"C,

RdC2O = d.c. resistance at 20°C

Rd, at 85°C = Rd@o [1 + azo(& - e,)] (28.6)

0, = Operating temperature = 85°C

where

= temperature coefficient of resistance for CIS- e, = Since the value of Rdc is available at 20°C

M grade of aluminium from Table 30.1, therefore, 0, = 20°C.

= 0.00403 Per "C at 20°C Rd, at 85°C = 0.0445 [1 + 0.00403 (85 - 20)]