Page 236 - Instrumentation Reference Book 3E

P. 236

220 Microprocessor-based and intelligent transmitters

Actual Liquid Flow Rate (rn3/h)

1 I I 1 I I 1 1 1 1 I 1 1 1 1 1 1 I I I I I I,,

10 20 30 50 100 200 300 500 I000 20003000 5000 1MHx)

Actual Gas and Steam Flow Rate (rn3/h)

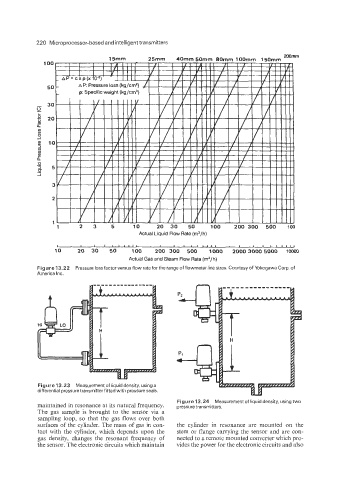

Figure 13.22 Pressure loss factor versus flow rate for the range of flowmeter line sizes. Courtesy of Yokogawa Corp. of

America Inc.

Figure 13.23 Measurement of liquiddensity, using a

differential pressure transmitter fitted with pressure seals.

Figure 13.24 Measurement of liquid density, using two

maintained in resonance at its natural frequency. pressure transmitters.

The gas sample is brought to the sensor via a

sampling loop, so that the gas flows over both

surfaces of the cylinder. The mass of gas in con- the cylinder in resonance are mounted on the

tact with the cylinder, which depends upon the stem or flange carrying the sensor and are con-

gas density, changes the resonant frequency of nected to a remote mounted converter which pro-

the sensor. The electronic circuits which maintain vides the power for the electronic circuits and also