Page 586 - Instrumentation Reference Book 3E

P. 586

568 Non-destructive testing

(b)

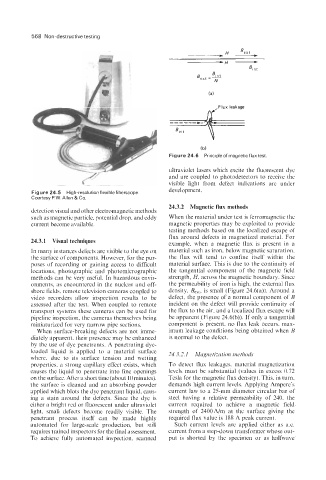

Figure 24.6 Principleof magneticflux test

ultraviolet lasers which excite the fluorescent dye

and are coupled to photodetectors to receive the

visible light from defect indications are under

development.

Figure 24.5 High-resolution flexible fiberscope.

Courtesy P.W. Allen & Co.

24.3.2 Magnetic flux methods

detection visual and other electromagnetic methods

such as magnetic particle, potential drop, and eddy When the material under test is ferromagnetic the

current become available. magnetic properties may be exploited to provide

testing methods based on the localized escape of

flux around defects in magnetized material. For

24.3.1 Visual techniques example, when a magnetic flux is present in a

In many instances defects are visible to the eye on material such as iron, below magnetic saturation,

the surface of components. However, for the pur- the flux will tend to confine itself within the

poses of recording or gaining access to difficult material surface. This is due to the continuity of

locations, photographic and photomicrographic the tangential component of the magnetic field

methods can be very useful. In hazardous envir- strength, H, across the magnetic boundary. Since

onments, as encountered in the nuclear and off- the permeability of iron is high, the external flux

shore fields, remote television cameras coupled to density, BeXt, is small (Figure 24.6(a)). Around a

video recorders allow inspection results to be defect, the presence of a normal component of B

assessed after the test. When coupled to remote incident on the defect will provide continuity of

transport systems these cameras can be used for the flux to the air, and a localized flux escape will

pipeline inspection, the cameras themselves being be apparent (Figure 24.6(b)). If only a tangential

miniaturized for very narrow pipe sections. component is present, no flux leak occurs, max-

When surface-breaking defects are not imme- imum leakage conditions being obtained when B

diately apparent. their presence may be enhanced is normal to the defect.

by the use of dye penetrants. A penetrating dye-

loaded liquid is applied to a material surface 24.3.2.1 Magnetization methods

where, due to its surface tension and wetting

properties, a strong capillary effect exists, which To detect flux leakages, material magnetization

causes the liquid to penetrate into fine openings levels must be substantial (values in excess 0.72

on the surface. After a short time (about 10 minutes), Tesla for the magnetic flux density). This. in turn,

the surface is cleaned and an absorbing powder demands high current levels. Applying Ampere's

applied which blots the dye penetrant liquid, caus- current law to a 25-mm diameter circular bar of

ing a stain around the defects. Since the dye is steel having a relative permeability of 240, the

either a bright red or fluorescent under ultraviolet current required to achieve a magnetic field

light, small defects become readily visible. The strength of 2400Nm at the surface giving the

penetrant process itself can be made highly required flux value is 188 A peak current.

automated for large-scale production, but still Such current levels are applied either as a.c.

requires trained inspectors for the final assessment. current from a step-down transformer whose out-

To achieve fully automated inspection, scanned put is shorted by the specimen or as halfwave