Page 588 - Instrumentation Reference Book 3E

P. 588

570 Non-destructive testing

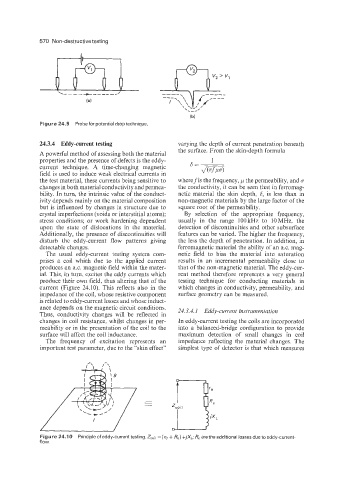

Figure 24.9 Probe for potential drop technique.

24.3.4 Eddy-current testing varying the depth of current penetration beneath

A powerful method of assessing both the material the surface. From the skin-depth formula

properties and the presence of defects is the eddy- 5=-------- 1

current technique. A time-changing magnetic drn

field is used to induce weak electrical currents in

the test material, these currents being sensitive to wherefis the frequency, p the permeability, and 0

changes in bothmaterial conductivity and permea- the conductivity, it can be seen that in ferromag-

bility. In turn, the intrinsic value of the conduct- netic material the skin depth, 6, is less than in

ivity depends mainly on the material composition non-magnetic materials by the large factor of the

but is influenced by changes in structure due to square root of the permeability.

crystal imperfections (voids or interstitial atoms); By selection of the appropriate frequency,

stress conditions; or work hardening dependent usually in the range lOOkHz to lOMHz, the

upon the state of dislocations in the material. detection of discontinuities and other subsurface

Additionally, the presence of discontinuities will features can be varied. The higher the frequency,

disturb the eddy-current flow patterns giving the less the depth of penetration. In addition, in

detectable changes. ferromagnetic material the ability of an a.c. mag-

The usual eddy-current testing system com- netic field to bias the material into saturation

prises a coil which due to the applied current results in an incremental permeability close to

produces an a.c. magnetic field within the mater- that of the non-magnetic material. The eddy-cur-

ial. This, in turn, excites the eddy currents which rent method therefore represents a very general

produce their own field, thus altering that of the testing technique for conducting materials in

current (Figure 24.10). This reflects also in the which changes in conductivity, permeability, and

impedance of the coil, whose resistive component surface geometry can be measured.

is related to eddy-current losses and whose induct-

ance depends on the magnetic circuit conditions. 24.3.4.1 Eddy-current instrumentation

Thus, conductivity changes will be reflected in

changes in coil resistance, whilst changes in per- In eddy-current testing the coils are incorporated

meability or in the presentation of the coil to the into a balanced-bridge configuration to provide

surface will affect the coil inductance. maximum detection of small changes in coil

The frequency of excitation represents an impedance reflecting the material changes. The

important test parameter, due to the “skin effect” simplest type of detector is that which measures

Figure 24.10 Principle of eddy-current testing. Z,,i, =(ro + R,)+jx~; Re are the additional losses due to eddy-current-

flow.