Page 598 - Instrumentation Reference Book 3E

P. 598

580 Non-destructive testing

Synchronization

Pulse

generator

i

Oscilloscope

Y

Wide-band 2

amplifier . 1

Transducer 1

Eia Spectrum

Specimen analyzer

Figure 24.23 Pulse-echo spectroscope.

Barium titanate-5 MHz

Swept Sweep signal

frequency

generator

- Lead metanlobate-10 MHZ

intensification X

2

Y I Lithium sul~hate-15 MHZ

Osci I loscope

Specimen

Figure 24.24 Pulsedfrequency-modulation

spectroscope.

M Hz

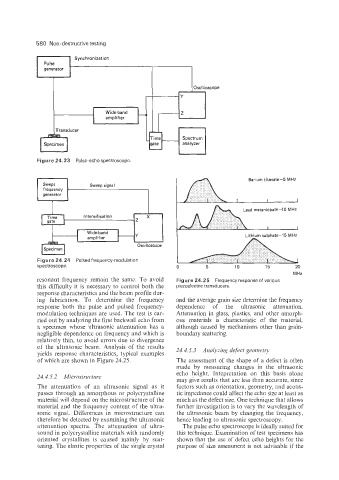

resonant frequency remain the same. To avoid Figure 24.25 Frequencyresponseof various

this difficulty it is necessary to control both the piezoelectric transducers.

response characteristics and the beam profile dur-

ing fabrication. To determine the frequency and the average grain size determine the frequency

response both the pulse and pulsed frequency- dependence of the ultrasonic attenuation.

modulation techniques are used. The test is car- Attenuation in glass, plastics, and other amorph-

ried out by analyzing the first backwall echo from ous materials is characteristic of the material,

a specimen whose ultrasonic attenuation has a although caused by mechanisms other than grain-

negligible dependence on frequency and which is boundary scattering.

relatively thin, to avoid errors due to divergence

of the ultrasonic beam. Analysis of the results 24.4.5.3 Analyzing defect geometry

yields response characteristics, typical examples

of which are shown in Figure 24.25. The assessment of the shape of a defect is often

made by measuring changes in the ultrasonic

echo height. Intepretation on this basis alone

24.4.5.2 Microstructure

may give results that are less than accurate, since

The attenuation of an ultrasonic signal as it factors such as orientation, geometry, and acous-

passes through an amorphous or polycrystalline tic impedance could affect the echo size at least as

material will depend on the microstructure of the much as the defect size. One technique that allows

material and the frequency content of the ultra- further investigation is to vary the wavelength of

sonic signal. Differences in microstructure can the ultrasonic beam by changing the frequency,

therefore be detected by examining the ultrasonic hence leading to ultrasonic spectroscopy.

attenuation spectra. The attenuation of ultra- The pulse echo spectroscope is ideally suited for

sound in polycrystalline materials with randomly this technique. Examination of test specimens has

oriented crystallites is caused mainly by scat- shown that the use of defect echo heights for the

tering. The elastic properties of the single crystal purpose of size assessment is not advisable if the