Page 120 - System on Package_ Miniaturization of the Entire System

P. 120

Stacked ICs and Packages (SIP) 95

In response to the need for higher-density printed wiring boards (PWBs), the 1980s saw

the development of surface-mount technology (SMT) and the quad-flat package (QFP).

Since packages such as QFP used in SMT have leads and not pins, they can be mounted

on both surfaces of the PWB, leading to higher-density packaging. The QFP allows a

lead frame to run around on all four sides of a square package, thus enabling higher pin

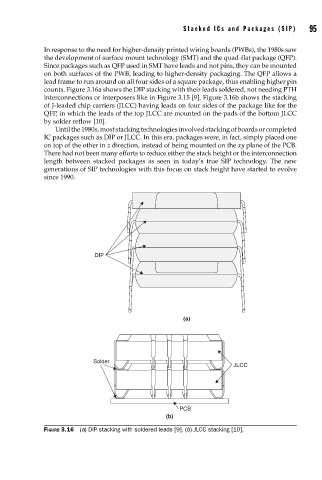

counts. Figure 3.16a shows the DIP stacking with their leads soldered, not needing PTH

interconnections or interposers like in Figure 3.15 [9]. Figure 3.16b shows the stacking

of J-leaded chip carriers (JLCC) having leads on four sides of the package like for the

QFP, in which the leads of the top JLCC are mounted on the pads of the bottom JLCC

by solder reflow [10].

Until the 1980s, most stacking technologies involved stacking of boards or completed

IC packages such as DIP or JLCC. In this era, packages were, in fact, simply placed one

on top of the other in z direction, instead of being mounted on the xy plane of the PCB.

There had not been many efforts to reduce either the stack height or the interconnection

length between stacked packages as seen in today’s true SIP technology. The new

generations of SIP technologies with this focus on stack height have started to evolve

since 1990.

DIP

(a)

Solder

JLCC

PCB

(b)

FIGURE 3.16 (a) DIP stacking with soldered leads [9]. (b) JLCC stacking [10].