Page 222 - Sami Franssila Introduction to Microfabrication

P. 222

Plasma-etched Structures 201

DRIE processes that use Cl 2 chemistry use metals such

as chromium or nickel as etch masks. Etching of thick

oxide structures (>10 µm) (for optical waveguides or

capillary electrophoresis channels) uses thick polysili-

con, amorphous silicon or metal masks.

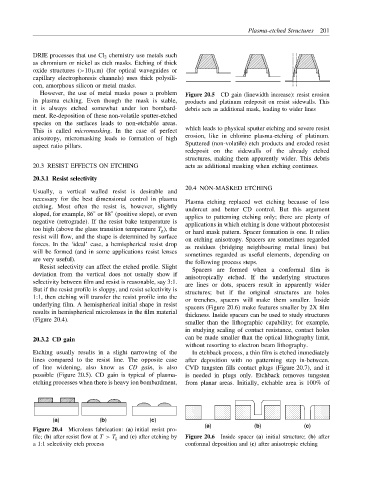

However, the use of metal masks poses a problem Figure 20.5 CD gain (linewidth increase): resist erosion

in plasma etching. Even though the mask is stable, products and platinum redeposit on resist sidewalls. This

it is always etched somewhat under ion bombard- debris acts as additional mask, leading to wider lines

ment. Re-deposition of these non-volatile sputter-etched

species on the surfaces leads to non-etchable areas.

This is called micromasking. In the case of perfect which leads to physical sputter etching and severe resist

anisotropy, micromasking leads to formation of high erosion, like in chlorine plasma-etching of platinum.

Sputtered (non-volatile) etch products and eroded resist

aspect ratio pillars.

redeposit on the sidewalls of the already etched

structures, making them apparently wider. This debris

20.3 RESIST EFFECTS ON ETCHING acts as additional masking when etching continues.

20.3.1 Resist selectivity

20.4 NON-MASKED ETCHING

Usually, a vertical walled resist is desirable and

necessary for the best dimensional control in plasma

Plasma etching replaced wet etching because of less

etching. Most often the resist is, however, slightly undercut and better CD control. But this argument

◦

◦

sloped, for example, 86 or 88 (positive slope), or even

applies to patterning etching only; there are plenty of

negative (retrograde). If the resist bake temperature is applications in which etching is done without photoresist

too high (above the glass transition temperature T g ), the or hard mask pattern. Spacer formation is one. It relies

resist will flow, and the shape is determined by surface on etching anisotropy. Spacers are sometimes regarded

forces. In the ‘ideal’ case, a hemispherical resist drop as residues (bridging neighbouring metal lines) but

will be formed (and in some applications resist lenses sometimes regarded as useful elements, depending on

are very useful). the following process steps.

Resist selectivity can affect the etched profile. Slight Spacers are formed when a conformal film is

deviation from the vertical does not usually show if anisotropically etched. If the underlying structures

selectivity between film and resist is reasonable, say 3:1. are lines or dots, spacers result in apparently wider

But if the resist profile is sloppy, and resist selectivity is structures; but if the original structures are holes

1:1, then etching will transfer the resist profile into the or trenches, spacers will make them smaller. Inside

underlying film. A hemispherical initial shape in resist spacers (Figure 20.6) make features smaller by 2X film

results in hemispherical microlenses in the film material

thickness. Inside spacers can be used to study structures

(Figure 20.4).

smaller than the lithographic capability; for example,

in studying scaling of contact resistance, contact holes

20.3.2 CD gain can be made smaller than the optical lithography limit,

without resorting to electron beam lithography.

Etching usually results in a slight narrowing of the In etchback process, a thin film is etched immediately

lines compared to the resist line. The opposite case after deposition with no patterning step in-between.

of line widening, also know as CD gain, is also CVD tungsten fills contact plugs (Figure 20.7), and it

possible (Figure 20.5). CD gain is typical of plasma- is needed in plugs only. Etchback removes tungsten

etching processes when there is heavy ion bombardment, from planar areas. Initially, etchable area is 100% of

(a) (b) (c)

(a) (b) (c)

Figure 20.4 Microlens fabrication: (a) initial resist pro-

file; (b) after resist flow at T > T g and (c) after etching by Figure 20.6 Inside spacer (a) initial structure; (b) after

a 1:1 selectivity etch process conformal deposition and (c) after anisotropic etching