Page 229 - Sami Franssila Introduction to Microfabrication

P. 229

208 Introduction to Microfabrication

Potentiostat

Working Cathodic Anodic

electrode 0.6

(Si wafer) Reference Counter Passivation potential

Current (mA/cm 2 ) 0.2

electrode electrode 0.4

n-Si p-Si 0 Oxide

Anodic −0.2 free Surface oxide

oxide −0.4 Etching No etching

Pt

Etching solution −0.4 0 0.4 0.8 1.2 1.6

Etch mask

Applied potential (Volts)

(a) (b)

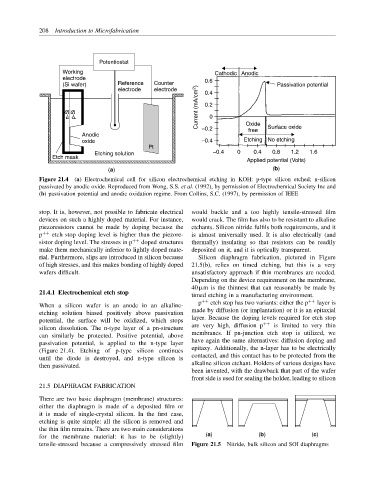

Figure 21.4 (a) Electrochemical cell for silicon electrochemical etching in KOH: p-type silicon etched; n-silicon

passivated by anodic oxide. Reproduced from Wong, S.S. et al. (1992), by permission of Electrochemical Society Inc and

(b) passivation potential and anodic oxidation regime. From Collins, S.C. (1997), by permission of IEEE

stop. It is, however, not possible to fabricate electrical would buckle and a too highly tensile-stressed film

devices on such a highly doped material. For instance, would crack. The film has also to be resistant to alkaline

piezoresistors cannot be made by doping because the etchants. Silicon nitride fulfils both requirements, and it

p ++ etch stop doping level is higher than the piezore- is almost universally used. It is also electrically (and

sistor doping level. The stresses in p ++ doped structures thermally) insulating so that resistors can be readily

make them mechanically inferior to lightly doped mate- deposited on it, and it is optically transparent.

rial. Furthermore, slips are introduced in silicon because Silicon diaphragm fabrication, pictured in Figure

of high stresses, and this makes bonding of highly doped 21.5(b), relies on timed etching, but this is a very

wafers difficult. unsatisfactory approach if thin membranes are needed.

Depending on the device requirement on the membrane,

40 µm is the thinnest that can reasonably be made by

21.4.1 Electrochemical etch stop

timed etching in a manufacturing environment.

p ++ etch stop has two variants: either the p ++ layer is

When a silicon wafer is an anode in an alkaline-

etching solution biased positively above passivation made by diffusion (or implantation) or it is an epitaxial

potential, the surface will be oxidized, which stops layer. Because the doping levels required for etch stop

++

silicon dissolution. The n-type layer of a pn-structure are very high, diffusion p is limited to very thin

can similarly be protected. Positive potential, above membranes. If pn-junction etch stop is utilized, we

passivation potential, is applied to the n-type layer have again the same alternatives: diffusion doping and

(Figure 21.4). Etching of p-type silicon continues epitaxy. Additionally, the n-layer has to be electrically

until the diode is destroyed, and n-type silicon is contacted, and this contact has to be protected from the

then passivated. alkaline silicon etchant. Holders of various designs have

been invented, with the drawback that part of the wafer

front side is used for sealing the holder, leading to silicon

21.5 DIAPHRAGM FABRICATION

There are two basic diaphragm (membrane) structures:

either the diaphragm is made of a deposited film or

it is made of single-crystal silicon. In the first case,

etching is quite simple: all the silicon is removed and

the thin film remains. There are two main considerations

for the membrane material: it has to be (slightly) (a) (b) (c)

tensile-stressed because a compressively stressed film Figure 21.5 Nitride, bulk silicon and SOI diaphragms