Page 235 - Sami Franssila Introduction to Microfabrication

P. 235

214 Introduction to Microfabrication

Si (111) Oxidization

[111] [111]

[111] (110)

(011) (101) Patterning

A′ 19.47°

A A

(101) (011)

[111] (110)

[111] [111] Dry etching

Flat

A′ A′ [110] <110>

(111)

120° 60° Cross section A A′

Etching

A

by EPW

60°

[111]

Baking of

solution

Top view Side view

(a)

Stripping of

laser cavity

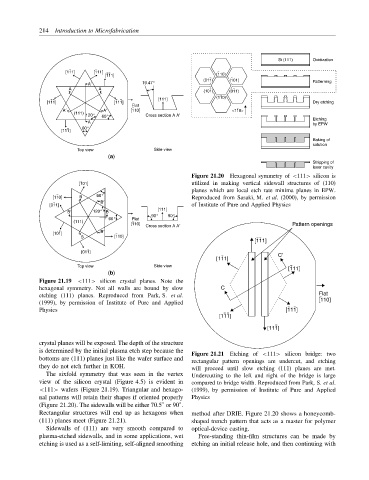

Figure 21.20 Hexagonal symmetry of <111> silicon is

[101] utilized in making vertical sidewall structures of (110)

planes which are local etch rate minima planes in EPW.

[110] B 60° Reproduced from Sasaki, M. et al. (2000), by permission

B′

[011] of Institute of Pure and Applied Physics

[111]

B′ 120° B

90° 90°

60° Flat

(111)

[110] Pattern openings

Cross section A A′

[101] B′

B [110]

[111]

[011]

C′

[111]

Top view Side view [111]

(b)

Figure 21.19 <111> silicon crystal planes. Note the

hexagonal symmetry. Not all walls are bound by slow C

etching (111) planes. Reproduced from Park, S. et al. Flat

[110]

(1999), by permission of Institute of Pure and Applied

Physics [111]

[111]

[111]

crystal planes will be exposed. The depth of the structure

is determined by the initial plasma etch step because the Figure 21.21 Etching of <111> silicon bridge: two

bottoms are (111) planes just like the wafer surface and

rectangular pattern openings are undercut, and etching

they do not etch further in KOH. will proceed until slow etching (111) planes are met.

The sixfold symmetry that was seen in the vertex Undercutting to the left and right of the bridge is large

view of the silicon crystal (Figure 4.5) is evident in compared to bridge width. Reproduced from Park, S. et al.

<111> wafers (Figure 21.19). Triangular and hexago- (1999), by permission of Institute of Pure and Applied

nal patterns will retain their shapes if oriented properly Physics

◦

◦

(Figure 21.20). The sidewalls will be either 70.5 or 90 .

Rectangular structures will end up as hexagons when method after DRIE. Figure 21.20 shows a honeycomb-

(111) planes meet (Figure 21.21). shaped trench pattern that acts as a master for polymer

Sidewalls of (111) are very smooth compared to optical-device casting.

plasma-etched sidewalls, and in some applications, wet Free-standing thin-film structures can be made by

etching is used as a self-limiting, self-aligned smoothing etching an initial release hole, and then continuing with