Page 237 - Sami Franssila Introduction to Microfabrication

P. 237

216 Introduction to Microfabrication

7. Design the process and mask for fabrication of silicon Nijdam, A.J. et al: Velocity sources as an explanation for

bridges on (110) wafers. experimentally observed variations in Si{111} etch rates, J.

8. Design a process to fabricate the duckbill valve Micromech. Microeng., 9 (1999), 135.

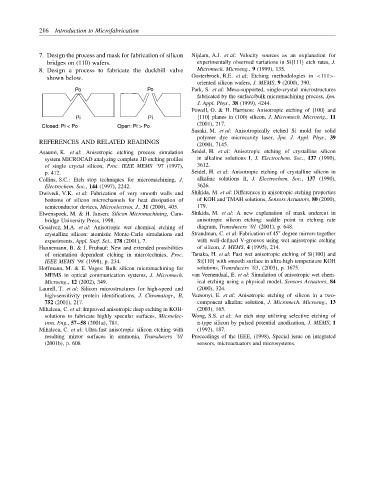

shown below. Oosterbroek, R.E. et al: Etching methodologies in <111>-

oriented silicon wafers, J. MEMS, 9 (2000), 390.

Po Po Park, S. et al: Mesa-supported, single-crystal microstructures

fabricated by the surface/bulk micromachining process, Jpn.

J. Appl. Phys., 38 (1999), 4244.

Powell, O. & H. Harrison: Anisotropic etching of {100} and

Pi Pi {110} planes in (100) silicon, J. Micromech. Microeng., 11

(2001), 217.

Closed: Pi < Po Open: Pi > Po

Sasaki, M. et al: Anisotropically etched Si mold for solid

polymer dye microcavity laser, Jpn. J. Appl. Phys., 39

REFERENCES AND RELATED READINGS (2000), 7145.

Asaumi, K. et al: Anisotropic etching process simulation Seidel, H. et al: Anisotropic etching of crystalline silicon

system MICROCAD analyzing complete 3D etching profiles in alkaline solutions I, J. Electrochem. Soc., 137 (1990),

of single crystal silicon, Proc. IEEE MEMS ’97 (1997), 3612.

p. 412. Seidel, H. et al: Anisotropic etching of crystalline silicon in

Collins, S.C.: Etch stop techniques for micromachining, J. alkaline solutions II, J. Electrochem. Soc., 137 (1990),

Electrochem. Soc., 144 (1997), 2242. 3626.

Dwivedi, V.K. et al: Fabrication of very smooth walls and Shikida, M. et al: Differences in anisotropic etching properties

bottoms of silicon microchannels for heat dissipation of of KOH and TMAH solutions, Sensors Actuators, 80 (2000),

semiconductor devices, Microelectron. J., 31 (2000), 405. 179.

Elwenspoek, M. & H. Jansen: Silicon Micromachining, Cam- Shikida, M. et al: A new explanation of mask undercut in

bridge University Press, 1998. anisotropic silicon etching: saddle point in etching rate

Gosalvez, M.A. et al: Anisotropic wet chemical etching of diagram, Transducers ’01 (2001), p. 648.

◦

crystalline silicon: atomistic Monte-Carlo simulations and Strandman, C. et al: Fabrication of 45 degree mirrors together

experiments, Appl. Surf. Sci., 178 (2001), 7. with well-defined V-grooves using wet anisotropic etching

Hannemann, B. & J. Fruhauf: New and extended possibilities of silicon, J. MEMS, 4 (1995), 214.

of orientation dependent etching in microtechnics, Proc. Tanaka, H. et al: Fast wet anisotropic etching of Si{100} and

IEEE MEMS ’98 (1998), p. 234. Si{110} with smooth surface in ultra-high temperature KOH

Hoffmann, M. & E. Voges: Bulk silicon micromachining for solutions, Transducers ’03, (2003), p. 1675.

MEMS in optical communication systems, J. Micromech. van Veenendaal, E. et al: Simulation of anisotropic wet chem-

Microeng., 12 (2002), 349. ical etching using a physical model, Sensors Actuators, 84

Laurell, T. et al: Silicon microstructures for high-speed and (2000), 324.

high-sensitivity protein identifications, J. Chromatogr., B, Vazsonyi, E. et al: Anisotropic etching of silicon in a two-

752 (2001), 217. component alkaline solution, J. Micromech. Microeng., 13

Mihalcea, C. et al: Improved anisotropic deep etching in KOH- (2003), 165.

solutions to fabricate highly specular surfaces, Microelec- Wong, S.S. et al: An etch stop utilizing selective etching of

tron. Eng., 57–58 (2001a), 781. n-type silicon by pulsed potential anodization, J. MEMS, 1

Mihalcea, C. et al: Ultra-fast anisotropic silicon etching with (1992), 187.

resulting mirror surfaces in ammonia, Transducers ’01 Proceedings of the IEEE, (1998), Special issue on integrated

(2001b), p. 608 sensors, microactuators and microsystems.