Page 295 - Sami Franssila Introduction to Microfabrication

P. 295

274 Introduction to Microfabrication

n poly emitter (poly #2)

+

CVD oxide spacer (oxide #2)

CVD oxide (oxide #1)

Base link p poly (poly #1)

+

+

Base link diffusion (p )

n emitter

p intrinsic base

Figure 26.5 Self-aligned double poly bipolar (see text for details)

◦

structure has to be etched. Etching of the base poly leads ca. 950 C required for poly doping by thermal diffusion

to some loss of the underlying single-crystal silicon too, or implantation annealing.

but the intrinsic base has not yet been made so its

depth is not affected. CVD oxide deposition determines

26.2.4 Lateral scaling

the distance between the link base and the intrinsic

base non-lithographically, in a self-aligned manner. The In a standard buried collector, bipolar devices are

emitter will be automatically aligned to the base, too. isolated from each other by guard-ring diffusions

Intrinsic base implant dose, energy and annealing are (Figure 26.1). The diffusion depth has to be equal to

optimized irrespective of link base properties. Emitter the epilayer thickness, and guard rings take up a lot of

poly is doped in situ in order to reduce thermal budget: area. LOCOS isolation, shown in Figure 26.3, becomes

◦

poly LPCVD temperature is ca. 600 C, as against the possible when epilayer thicknesses become similar to

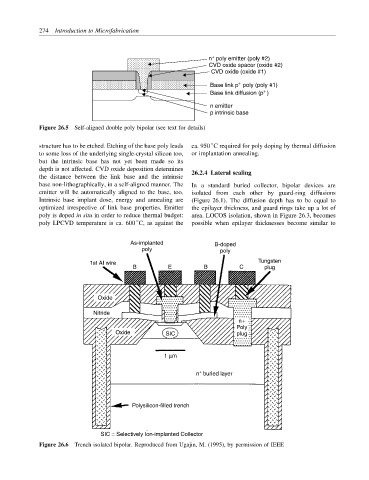

As-implanted B-doped

poly poly

1st AI wire Tungsten

B E B C plug

Oxide

Nitride

n+

Poly

Oxide SIC plug

1 µm

+

n buried layer

Polysilicon-filled trench

SIC = Selectively Ion-implanted Collector

Figure 26.6 Trench isolated bipolar. Reproduced from Ugajin, M. (1995), by permission of IEEE