Page 296 - Sami Franssila Introduction to Microfabrication

P. 296

Bipolar Technology 275

NPN bipolar + +

+

N + N + P + P + N P base N collector

NMOS PMOS emitter contact contact

P-EPI N-well

P-base N-well (collector)

P substrate

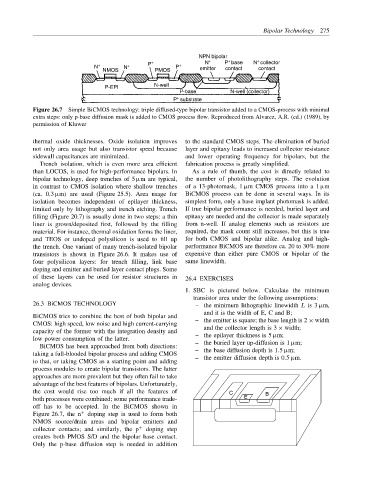

+

Figure 26.7 Simple BiCMOS technology: triple diffused-type bipolar transistor added to a CMOS-process with minimal

extra steps: only p-base diffusion mask is added to CMOS process flow. Reproduced from Alvarez, A.R. (ed.) (1989), by

permission of Kluwer

thermal oxide thicknesses. Oxide isolation improves to the standard CMOS steps. The elimination of buried

not only area usage but also transistor speed because layer and epitaxy leads to increased collector resistance

sidewall capacitances are minimized. and lower operating frequency for bipolars, but the

Trench isolation, which is even more area efficient fabrication process is greatly simplified.

than LOCOS, is used for high-performance bipolars. In As a rule of thumb, the cost is directly related to

bipolar technology, deep trenches of 5 µm are typical, the number of photolithography steps. The evolution

in contrast to CMOS isolation where shallow trenches of a 13-photomask, 1 µm CMOS process into a 1 µm

(ca. 0.3 µm) are used (Figure 25.5). Area usage for BiCMOS process can be done in several ways. In its

isolation becomes independent of epilayer thickness, simplest form, only a base implant photomask is added.

limited only by lithography and trench etching. Trench If true bipolar performance is needed, buried layer and

filling (Figure 20.7) is usually done in two steps: a thin epitaxy are needed and the collector is made separately

liner is grown/deposited first, followed by the filling from n-well. If analog elements such as resistors are

material. For instance, thermal oxidation forms the liner, required, the mask count still increases, but this is true

and TEOS or undoped polysilicon is used to fill up for both CMOS and bipolar alike. Analog and high-

the trench. One variant of many trench-isolated bipolar performance BiCMOS are therefore ca. 20 to 30% more

transistors is shown in Figure 26.6. It makes use of expensive than either pure CMOS or bipolar of the

four polysilicon layers: for trench filling, link base same linewidth.

doping and emitter and buried layer contact plugs. Some

of these layers can be used for resistor structures in 26.4 EXERCISES

analog devices.

1. SBC is pictured below. Calculate the minimum

transistor area under the following assumptions:

26.3 BiCMOS TECHNOLOGY – the minimum lithographic linewidth L is 3 µm,

and it is the width of E, C and B;

BiCMOS tries to combine the best of both bipolar and

– the emitter is square; the base length is 2 × width

CMOS: high speed, low noise and high current-carrying

and the collector length is 3 × width;

capacity of the former with the integration density and

– the epilayer thickness is 5 µm;

low power consumption of the latter.

BiCMOS has been approached from both directions: – the buried layer up-diffusion is 1 µm;

taking a full-blooded bipolar process and adding CMOS – the base diffusion depth is 1.5 µm;

to that, or taking CMOS as a starting point and adding – the emitter diffusion depth is 0.5 µm.

process modules to create bipolar transistors. The latter

approaches are more prevalent but they often fail to take

advantage of the best features of bipolars. Unfortunately,

the cost would rise too much if all the features of C B

both processes were combined; some performance trade- E

off has to be accepted. In the BiCMOS shown in

Figure 26.7, the n + doping step is used to form both

NMOS source/drain areas and bipolar emitters and

collector contacts; and similarly, the p + doping step

creates both PMOS S/D and the bipolar base contact.

Only the p-base diffusion step is needed in addition