Page 300 - Sami Franssila Introduction to Microfabrication

P. 300

Multilevel Metallization 279

1st interconnect

Goal (contact plug)

Silicon

Silicon

Cleaning Selective W Sputter TIN Sputter Al

Cleaning Sputter Tl Sputter TIN Sputter Al

Cleaning Sputter Tl Sputter TIN Blanket W

Etchback (W)

Etchback (TIN) Sputter TIN Sputter AI

Figure 27.4 Three different routes to Ti/TiN/W/Al contact plug fill. Reproduced from Ohba, T. (1992), by permission

of Materials Research Soc

Aluminum global wiring

Tungsten plugs

Tungsten local wires

TiSi 2 /polysilicon gates

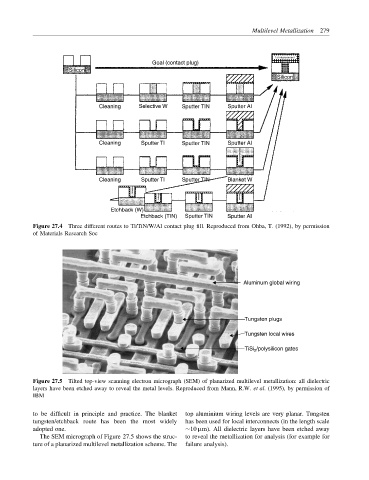

Figure 27.5 Tilted top-view scanning electron micrograph (SEM) of planarized multilevel metallization: all dielectric

layers have been etched away to reveal the metal levels. Reproduced from Mann, R.W. et al. (1995), by permission of

IBM

to be difficult in principle and practice. The blanket top aluminium wiring levels are very planar. Tungsten

tungsten/etchback route has been the most widely has been used for local interconnects (in the length scale

adopted one. ∼10 µm). All dielectric layers have been etched away

The SEM micrograph of Figure 27.5 shows the struc- to reveal the metallization for analysis (for example for

ture of a planarized multilevel metallization scheme. The failure analysis).