Page 53 - MEMS and Microstructures in Aerospace Applications

P. 53

Osiander / MEMS and microstructures in Aerospace applications DK3181_c003 Final Proof page 43 1.9.2005 8:59pm

MEMS Fabrication 43

TABLE 3.2

Common Crystalline Silicon Etchants’ Selectivity and Etch Rates

Etchant Etch Rate

18HF þ 4HNO 3 þ 3Si ! 2H 2 SiF 6 þ 4NO þ 8H 2 O Nonselective

{1 0 0} 0.14 m/min

Si þ H 2 O þ 2KOH ! K 2 SiO 3 þ 2H 2

{1 1 1} 0.0035 m/min

SiO 2 0.0014 m/min

SiN 4 not etched

Ethylene diamine pyrocatechol (EDP) {1 0 0} 0.75 m/min

{1 1 1} 0.021 m/min

SiO 2 0.0002 m/min

SiN 4 0.0001 m/min

Tetramethylammonium hydroxide (TMAH) {100} 1.0 m/min

{1 1 1} 0.029 m/min

SiO 2 0.0002 m/min

SiN 4 0.0001 m/min

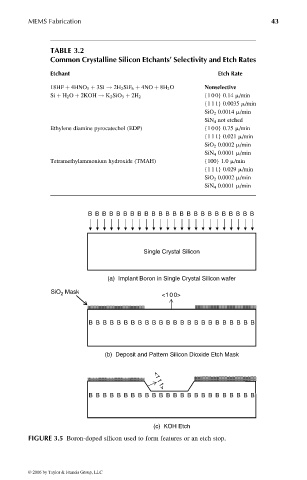

BBBBBBBBBBBBBBBBBBBBBBBB

Single Crystal Silicon

(a) Implant Boron in Single Crystal Silicon wafer

SiO Mask <100>

2

BBBBBBBBBBBBBBBBBBBBBBBB

(b) Deposit and Pattern Silicon Dioxide Etch Mask

<111>

BBBBBBBBBBBBBBBBBBBBBBBB

(c) KOH Etch

FIGURE 3.5 Boron-doped silicon used to form features or an etch stop.

© 2006 by Taylor & Francis Group, LLC