Page 54 - MEMS and Microstructures in Aerospace Applications

P. 54

Osiander / MEMS and microstructures in Aerospace applications DK3181_c003 Final Proof page 44 1.9.2005 8:59pm

44 MEMS and Microstructures in Aerospace Applications

Container

Diffused or

implanted n-type

+ silicon region

P-type silicon

V

Mask

Etchant

Electrode Container

(a) Electrochemical Etch Schematic

(b) Completed Structure

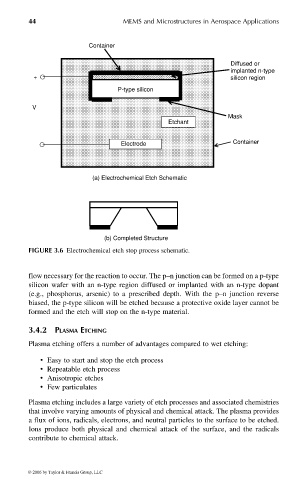

FIGURE 3.6 Electrochemical etch stop process schematic.

flow necessary for the reaction to occur. The p–n junction can be formed on a p-type

silicon wafer with an n-type region diffused or implanted with an n-type dopant

(e.g., phosphorus, arsenic) to a prescribed depth. With the p–n junction reverse

biased, the p-type silicon will be etched because a protective oxide layer cannot be

formed and the etch will stop on the n-type material.

3.4.2 PLASMA ETCHING

Plasma etching offers a number of advantages compared to wet etching:

. Easy to start and stop the etch process

. Repeatable etch process

. Anisotropic etches

. Few particulates

Plasma etching includes a large variety of etch processes and associated chemistries

that involve varying amounts of physical and chemical attack. The plasma provides

a flux of ions, radicals, electrons, and neutral particles to the surface to be etched.

Ions produce both physical and chemical attack of the surface, and the radicals

contribute to chemical attack.

© 2006 by Taylor & Francis Group, LLC