Page 63 - MEMS and Microstructures in Aerospace Applications

P. 63

Osiander / MEMS and microstructures in Aerospace applications DK3181_c003 Final Proof page 53 1.9.2005 8:59pm

MEMS Fabrication 53

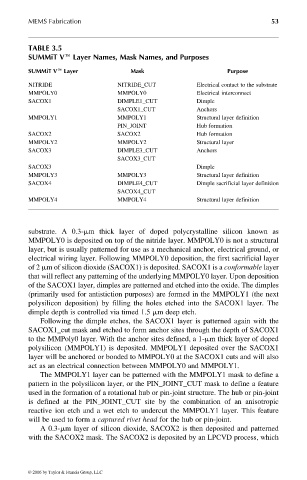

TABLE 3.5

SUMMiT Ve Layer Names, Mask Names, and Purposes

SUMMiT Ve Layer Mask Purpose

NITRIDE NITRIDE_CUT Electrical contact to the substrate

MMPOLY0 MMPOLY0 Electrical interconnect

SACOX1 DIMPLE1_CUT Dimple

SACOX1_CUT Anchors

MMPOLY1 MMPOLY1 Structural layer definition

PIN_JOINT Hub formation

SACOX2 SACOX2 Hub formation

MMPOLY2 MMPOLY2 Structural layer

SACOX3 DIMPLE3_CUT Anchors

SACOX3_CUT

SACOX3 Dimple

MMPOLY3 MMPOLY3 Structural layer definition

SACOX4 DIMPLE4_CUT Dimple sacrificial layer definition

SACOX4_CUT

MMPOLY4 MMPOLY4 Structural layer definition

substrate. A 0.3-mm thick layer of doped polycrystalline silicon known as

MMPOLY0 is deposited on top of the nitride layer. MMPOLY0 is not a structural

layer, but is usually patterned for use as a mechanical anchor, electrical ground, or

electrical wiring layer. Following MMPOLY0 deposition, the first sacrificial layer

of 2 mm of silicon dioxide (SACOX1) is deposited. SACOX1 is a conformable layer

that will reflect any patterning of the underlying MMPOLY0 layer. Upon deposition

of the SACOX1 layer, dimples are patterned and etched into the oxide. The dimples

(primarily used for antistiction purposes) are formed in the MMPOLY1 (the next

polysilicon deposition) by filling the holes etched into the SACOX1 layer. The

dimple depth is controlled via timed 1.5 mm deep etch.

Following the dimple etches, the SACOX1 layer is patterned again with the

SACOX1_cut mask and etched to form anchor sites through the depth of SACOX1

to the MMPoly0 layer. With the anchor sites defined, a 1-mm thick layer of doped

polysilicon (MMPOLY1) is deposited. MMPOLY1 deposited over the SACOX1

layer will be anchored or bonded to MMPOLY0 at the SACOX1 cuts and will also

act as an electrical connection between MMPOLY0 and MMPOLY1.

The MMPOLY1 layer can be patterned with the MMPOLY1 mask to define a

pattern in the polysilicon layer, or the PIN_JOINT_CUT mask to define a feature

used in the formation of a rotational hub or pin-joint structure. The hub or pin-joint

is defined at the PIN_JOINT_CUT site by the combination of an anisotropic

reactive ion etch and a wet etch to undercut the MMPOLY1 layer. This feature

will be used to form a captured rivet head for the hub or pin-joint.

A 0.3-mm layer of silicon dioxide, SACOX2 is then deposited and patterned

with the SACOX2 mask. The SACOX2 is deposited by an LPCVD process, which

© 2006 by Taylor & Francis Group, LLC