Page 60 - MEMS and Microstructures in Aerospace Applications

P. 60

Osiander / MEMS and microstructures in Aerospace applications DK3181_c003 Final Proof page 50 1.9.2005 8:59pm

50 MEMS and Microstructures in Aerospace Applications

Conformable

structural layer

Patterned

sacrificial

layer

Anisotropic etch of

top structural layer

Floating structural

Release etch leaving layer “stringer”

floating stringer

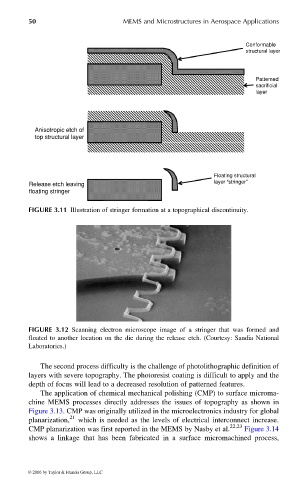

FIGURE 3.11 Illustration of stringer formation at a topographical discontinuity.

FIGURE 3.12 Scanning electron microscope image of a stringer that was formed and

floated to another location on the die during the release etch. (Courtesy: Sandia National

Laboratories.)

The second process difficulty is the challenge of photolithographic definition of

layers with severe topography. The photoresist coating is difficult to apply and the

depth of focus will lead to a decreased resolution of patterned features.

The application of chemical mechanical polishing (CMP) to surface microma-

chine MEMS processes directly addresses the issues of topography as shown in

Figure 3.13. CMP was originally utilized in the microelectronics industry for global

21

planarization, which is needed as the levels of electrical interconnect increase.

22,23

CMP planarization was first reported in the MEMS by Nasby et al. Figure 3.14

shows a linkage that has been fabricated in a surface micromachined process,

© 2006 by Taylor & Francis Group, LLC