Page 286 - Mechanical design of microresonators _ modeling and applications

P. 286

0-07-145538-8_CH05_285_08/30/05

Resonant Micromechanical Systems

Resonant Micromechanical Systems 285

α

Figure 5.59 Displaced fixed-free microcantilever.

flexure hinges

resistive actuation mass piezoresistive sensing

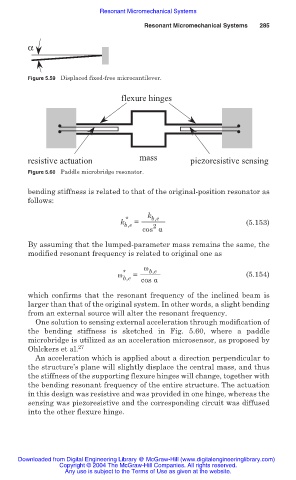

Figure 5.60 Paddle microbridge resonator.

bending stiffness is related to that of the original-position resonator as

follows:

k b,e

*

k b,e = (5.153)

2

cos Į

By assuming that the lumped-parameter mass remains the same, the

modified resonant frequency is related to original one as

Ȧ b,e

Ȧ * = (5.154)

b,e cos Į

which confirms that the resonant frequency of the inclined beam is

larger than that of the original system. In other words, a slight bending

from an external source will alter the resonant frequency.

One solution to sensing external acceleration through modification of

the bending stiffness is sketched in Fig. 5.60, where a paddle

microbridge is utilized as an acceleration microsensor, as proposed by

Ohlckers et al. 27

An acceleration which is applied about a direction perpendicular to

the structure’s plane will slightly displace the central mass, and thus

the stiffness of the supporting flexure hinges will change, together with

the bending resonant frequency of the entire structure. The actuation

in this design was resistive and was provided in one hinge, whereas the

sensing was piezoresistive and the corresponding circuit was diffused

into the other flexure hinge.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.