Page 84 - Mechanical Engineers Reference Book

P. 84

Electrical machines 2/25

where N, is the speed of the field (revimin) and f is the

frequency of the supply currents. The speed of the rotating

field is termed the ‘synchronous speed’ and for an equivalent

single pair of poles (i.e. three coils) this is 3000 revimin when

the frequency of the supply curients is at 50 Hz.

The use of a.c. excited rotor coiis to produce the rotating

magnetic field simplifies the mechanical construction of the

rotor and greatly facilitates the dynamic balancing of the

machine. An added advantage is that the waveform of the

generated voltage is improved. The a.c. method of exciting the

field is used extensively in large alternators. Salient pole rotors

are normally restricted to the smaller machines.

2.2.20 Synchronous motors

Synchronous motors are so called because they operate at only

one speed, i.e. the speed of the rotating field. The mechanical

construction is exactly the same as the alternator shown in

Figure 2.47. The field is supplied from a d.c. source and the

stator coils with a three-phase current. The rotating magnetic

field is induced by the stator coils and the rotor, which may be

I I likened to a permanent bar magnet, aligns itself to the rotating

flux produced in the stator. When a mechanical load is driven

by the shaft the field produced by the rotor is pulled out of

alignment with that produced by the stator. The angle of

misalignment is called the ‘load angle’. The characteristics of

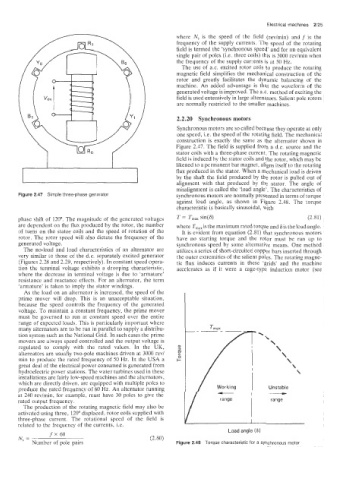

Figure 2.47 Simple three-phase generator synchronous motors are normally presented in terms of torque

against load angle, as shown in Figure 2.48. The torque

characteristic is basically sinusoidal, with

phase shift of 120”. The magnitude of the generated voltages T = T,,, sin(8) (2.81)

are dependent on the flux produced by the rotor, the number where T,,, is the maximum rated torque and 6 is the load angle.

3f turn(; on the stator coils and the speed of rotation of the It is evident from equation (2.81) that synchronous motors

rotor. The rotor speed will also dictate the frequency of the have no starting torque and the rotor must be run :up tQ

generated voltage. synchronous speed by some alternative means. One method

The no-load and load characteristics of an alternator are utilizes a series of short-circuited copper bars inserted through

very similar io those of the d.c. separately excited generator the outer extremities of the salient poles. The rotating magne-

(Figures 2.28 and 2.29, respectively). In constant speed opera- tic flux induces currents in these ‘grids’ and the machine

tion the terminal voltage exhibits a drooping characteristic, accelerates as if it were a cage-type induction motor (see

where the decrease in terminal voltage is due to ’armature’

resistance and reactance effects. For an alternator, the term

‘armature’ is taken to imply the stator windings.

As the load on an alternator is increased, the speed of the

pime mover will drop. This is an unacceptable situation,

because the speed controls the frequency of the generated

voltage. To maintain a constant frequency, the prime mover

must be governed to run at constant speed over the entire

range of expected loads. This is particularly important where

many alternators are to be run in parallel to supply a distribu-

tion system such as the National Grid. In such cases the prime

movers are aiways speed controlled and the output voltage is

regulated to comply with the rated values. In the UK, er

3

akernators are usually two-pole machines driven at 3000 rev/ IT

min to produce the rated frequency of 50 Hz. In the USA a c

great deal of the electrical power consumed is generated from

hydroelectric power stations. The water turbines used in these

installations are fairly low-speed machines and the alternators,

which aire directly driven, are equipped with multiple poles to

produce the rated frequency of 60 Hz. An alternator running Unstable

at 240 revimin, for example, must have 30 poles to give the

rated output frequency.

The production of the rotating magnetic field may also be

activated using three, 120” displaced, rotor coils supplied with

three-phase current. The rotational speed of the field is I

related ‘to the frequency of the currents, Le.

Load angle (6)

fx60

N =- (2.80)

Number of pole pairs Figure 2.48 Torque characteristic for a synchronous motor