Page 86 - Mechanical Engineers Reference Book

P. 86

--

Electrical machines 2127

Three-phase supply 2.2.24.1 Change of supply current frequency

Solid state variable-frequency drives first began to appear in

1968. They were originally applied to the control of synchro-

nous a.c. motors in the synthetic fibre industry and rapidly

---- gained acceptance in that particular market. In more recent

times they have been used in applications such as pumping,

1

I

synchronized press lines, conveyor lines and, to a lesser

extent, in the machine-tool industry as spindle drives. Modern

a.c. variable-frequency motors are available in power ratings

ranging from 1 kW to 750 kW and with speed ranges from l0il

to 10011.

2.2.24.2 Change of number of poles

By bringing out the ends of the stator coils to a specially

designed switch it becomes possible to change an induction

motor from one pole configuration to another. To obtain three

different pole numbers, and hence three different speeds, a

fairly complex switching device would be required.

Changing the number of poles gives a discrete change in

I motor speed, with little variation in speed over the switched

I range. For many applications, however, two discrete speeds

1 Start are all that is required and changing the number of poles is a

simple and effective method of achieving this.

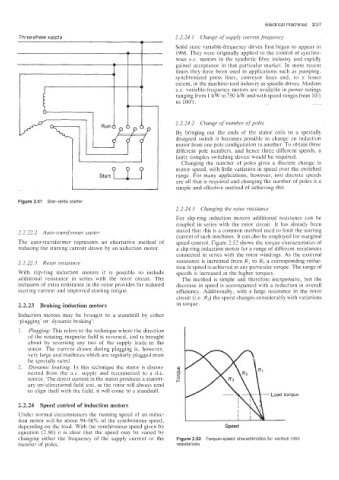

Figure 2.51 Stardelta starter

2.2.24.3 Changing the rotor resistance

For slip-ring induction motors additional resistance can be

coupled in series with the rotor circuit. It has already been

2.2.22.2 Auto-transformer starter stated that this is a common method used to limit the starting

current of such machines. It can also be employed for marginal

The aulo-transformer represents an alternative method of speed control. Figure 2.52 shows the torque characteristics of

reducing the starting current drawn by an induction motor. a slip-ring induction motor for a range of different resistances

connected in series with the rotor windings. As the external

2.2.22.3 Rotor resistance resistance is increased from R1 to R3 a corresponding reduc-

tion in speed is achieved at any particular torque. The range of

With slip-ring induction motors it is possible to include speeds is increased at the higher torques.

additional resistance in series with the rotor circuit. The The method is simple and therefore inexpensive, but the

inclusion of extra resistance in the rotor provides for reduced decrease in speed is accompanied with a reduction in overall

starting current and improved starting torque. efficiency. Additionally, with a large resistance in the rotor

circuit (i.e. R3) the speed changes considerably with variations

2.2.23 Braking induction motors in torque.

Induction motors may be brought to a standstill by either

’p!ugging’ or dynamic braking’:

1. Plugging: This refers to the technique where the direction

of the rotating magnetic field is reversed, and is brought

about by reversing any two of the supply leads to the

stator. The current drawn during plugging is, however,

very large and machines which are regularly plugged must

be specially rated.

2. Dynamic braking: In this technique the stator is discon-

nected from the a.c. supply and reconnected to a d.c.

source. The direct current in the stator produces a station-

ary unidirectional field and, as the rotor will always tend

to align itself with the field, it will come to a standstill.

2.2.24 Speed control of induction motors

Under normal circumstances the running speed of an induc-

tion motor will be about 9498% of the synchronous speed,

depending on the load. With the synchronous speed given by Speed

equation (2.80) it is clear that the speed may be varied by

changing either the frequency of the supply current or the Figure 2.52 Torque-speed characteristics for various rotor

number of poles. resistances