Page 104 - Mechanics of Microelectromechanical Systems

P. 104

2. Microcantilevers, microhinges, microbridges 91

Figure 2.16 is the plot of the ratio formulated in Eq. (2.90) in terms of the

friction coefficient and the height h of the microcantilever’s tip. It can be

seen that the circularly-filleted microcantilever can rotate up to 65 % more at

its tip than the elliptical design, and that the ratio between the tip slopes of

the two designs increases quasi-linearly when both and h are increasing.

2.3 Hollow Microcantilevers

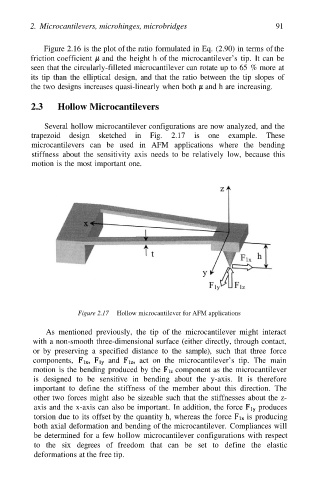

Several hollow microcantilever configurations are now analyzed, and the

trapezoid design sketched in Fig. 2.17 is one example. These

microcantilevers can be used in AFM applications where the bending

stiffness about the sensitivity axis needs to be relatively low, because this

motion is the most important one.

Figure 2.17 Hollow microcantilever for AFM applications

As mentioned previously, the tip of the microcantilever might interact

with a non-smooth three-dimensional surface (either directly, through contact,

or by preserving a specified distance to the sample), such that three force

components, and act on the microcantilever’s tip. The main

motion is the bending produced by the component as the microcantilever

is designed to be sensitive in bending about the y-axis. It is therefore

important to define the stiffness of the member about this direction. The

other two forces might also be sizeable such that the stiffnesses about the z-

axis and the x-axis can also be important. In addition, the force produces

torsion due to its offset by the quantity h, whereas the force is producing

both axial deformation and bending of the microcantilever. Compliances will

be determined for a few hollow microcantilever configurations with respect

to the six degrees of freedom that can be set to define the elastic

deformations at the free tip.