Page 105 - Mechanics of Microelectromechanical Systems

P. 105

92 Chapter 2

As shown previously, the tip slopes and as well as the tip

deflection might be available experimentally, which can aid in

determining the forces on the microcantilevers via compliances/stiffnesses.

2.3.1 Rectangular Design

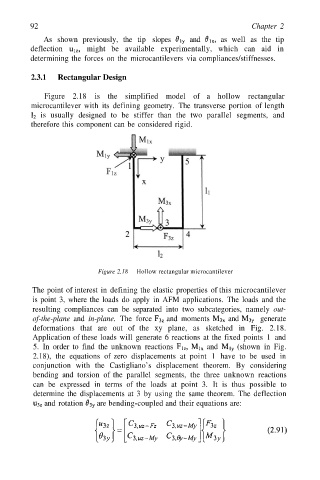

Figure 2.18 is the simplified model of a hollow rectangular

microcantilever with its defining geometry. The transverse portion of length

is usually designed to be stiffer than the two parallel segments, and

therefore this component can be considered rigid.

Figure 2.18 Hollow rectangular microcantilever

The point of interest in defining the elastic properties of this microcantilever

is point 3, where the loads do apply in AFM applications. The loads and the

resulting compliances can be separated into two subcategories, namely out-

of-the-plane and in-plane. The force and moments and generate

deformations that are out of the xy plane, as sketched in Fig. 2.18.

Application of these loads will generate 6 reactions at the fixed points 1 and

5. In order to find the unknown reactions and (shown in Fig.

2.18), the equations of zero displacements at point 1 have to be used in

conjunction with the Castigliano’s displacement theorem. By considering

bending and torsion of the parallel segments, the three unknown reactions

can be expressed in terms of the loads at point 3. It is thus possible to

determine the displacements at 3 by using the same theorem. The deflection

and rotation are bending-coupled and their equations are: