Page 194 - Mechatronic Systems Modelling and Simulation with HDLs

P. 194

8.3 DEMONSTRATOR 6: MICROMIRROR 183

this micromirror, see K¨ uck et al. [209], is a system manufactured using CMOS

compatible surface micromechanics. It is operated as an actuator, i.e. the mechan-

ical displacement is not the object of the measurement, but rather the system

behaviour to be caused. Here the deflection consists of the lowering of the mirror.

If light falls on the mirror its deflection brings about a corresponding phase shift

in the reflected light. The picture to be generated finally arises from the resulting

interferences. The deflection is achieved electrostatically.

8.3.1 System description

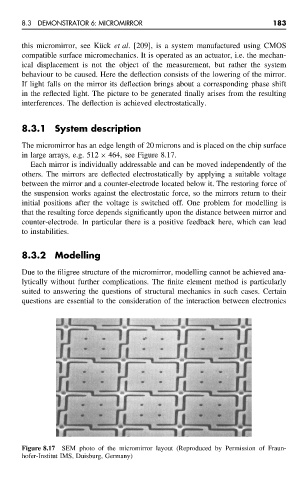

The micromirror has an edge length of 20 microns and is placed on the chip surface

in large arrays, e.g. 512 × 464, see Figure 8.17.

Each mirror is individually addressable and can be moved independently of the

others. The mirrors are deflected electrostatically by applying a suitable voltage

between the mirror and a counter-electrode located below it. The restoring force of

the suspension works against the electrostatic force, so the mirrors return to their

initial positions after the voltage is switched off. One problem for modelling is

that the resulting force depends significantly upon the distance between mirror and

counter-electrode. In particular there is a positive feedback here, which can lead

to instabilities.

8.3.2 Modelling

Due to the filigree structure of the micromirror, modelling cannot be achieved ana-

lytically without further complications. The finite element method is particularly

suited to answering the questions of structural mechanics in such cases. Certain

questions are essential to the consideration of the interaction between electronics

Figure 8.17 SEM photo of the micromirror layout (Reproduced by Permission of Fraun-

hofer-Institut IMS, Duisburg, Germany)