Page 173 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 173

SACRIFICIAL LAYER TECHNOLOGY 153

Bushing mould

Bushing Rotor

(b)

Bearing anchor

Bearing

JH Poly-Si Illllll Silicon nitride

Silicon dioxide | | (Silicon) substrate

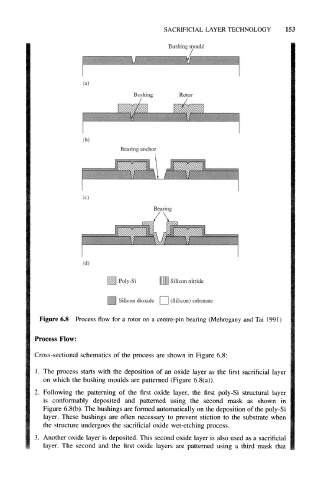

Figure 6.8 Process flow for a rotor on a centre-pin bearing (Mehregany and Tai 1991)

Process Flow:

Cross-sectional schematics of the process are shown in Figure 6.8:

1. The process starts with the deposition of an oxide layer as the first sacrificial layer

on which the bushing moulds are patterned (Figure 6.8(a)).

2. Following the patterning of the first oxide layer, the first poly-Si structural layer

is conformably deposited and patterned using the second mask as shown in

Figure 6.8(b). The bushings are formed automatically on the deposition of the poly-Si

layer. These bushings are often necessary to prevent stiction to the substrate when

the structure undergoes the sacrificial oxide wet-etching process.

3. Another oxide layer is deposited. This second oxide layer is also used as a sacrificial

layer. The second and the first oxide layers are patterned using a third mask that