Page 178 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 178

158 SILICON MICROMACHINING: SURFACE

(b)

Diaphragm Electrode

(Acoustic)

Backplate hole

(c)

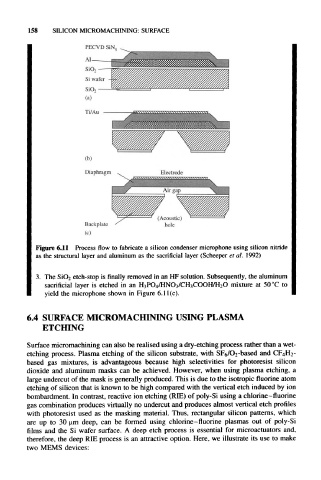

Figure 6.11 Process flow to fabricate a silicon condenser microphone using silicon nitride

as the structural layer and aluminum as the sacrificial layer (Scheeper et al. 1992)

3. The SiO 2 etch-stop is finally removed in an HF solution. Subsequently, the aluminum

sacrificial layer is etched in an H 3PO 4/HNO 3/CH 3COOH/H 2O mixture at 50 °C to

yield the microphone shown in Figure 6.11 (c).

6.4 SURFACE MICROMACHINING USING PLASMA

ETCHING

Surface micromachining can also be realised using a dry-etching process rather than a wet-

etching process. Plasma etching of the silicon substrate, with SFe/CVbased and CF 4H2-

based gas mixtures, is advantageous because high selectivities for photoresist silicon

dioxide and aluminum masks can be achieved. However, when using plasma etching, a

large undercut of the mask is generally produced. This is due to the isotropic fluorine atom

etching of silicon that is known to be high compared with the vertical etch induced by ion

bombardment. In contrast, reactive ion etching (REE) of poly-Si using a chlorine-fluorine

gas combination produces virtually no undercut and produces almost vertical etch profiles

with photoresist used as the masking material. Thus, rectangular silicon patterns, which

are up to 30 urn deep, can be formed using chlorine-fluorine plasmas out of poly-Si

films and the Si wafer surface. A deep etch process is essential for microactuators and,

therefore, the deep RIE process is an attractive option. Here, we illustrate its use to make

two MEMS devices: